Galvanic isolation: purpose and methods. What is galvanic isolation? The series of articles consists of three parts

The series of articles consists of three parts:

Interference in circuits.

During normal operation electronic device There may be interference in the circuit.

Interference can not only interfere with the normal operation of the device, but also lead to its complete failure.

Rice. 1. Interference in the useful signal.

You can see the interference on the oscilloscope screen by including it in the part of the circuit under study (Fig. 1). The duration of interference can be either very short (a few nanoseconds, so-called “needles”) or very long (several seconds). The shape and polarity of the interference also varies.

The propagation (passage) of interference occurs not only along the wire connections of the circuit, but sometimes even between parts of the circuit that are not connected by wires. In addition, interference can overlap and add up to each other. Thus, a single weak interference may not cause a malfunction in the device circuit, but the simultaneous accumulation of several weak random interferences leads to incorrect operation of the device. This fact makes the search and elimination of interference many times more difficult, since it takes on an even more random nature.

Sources of interference can be roughly divided:

- External source of interference. A strong electromagnetic or electrostatic field source near the device may cause the electronic device to malfunction. For example, a lightning discharge, relay switching of high currents or electric welding.

- Internal source of interference. For example, when you turn on/off a reactive load (an electric motor or an electromagnet) in a device, the rest of the circuit may malfunction. An incorrect program algorithm can also be a source of internal interference.

To protect against external interference, the structure or its individual parts are placed in a metal or electromagnetic shield, and circuit solutions with less sensitivity to external interference are also used. The use of filters, optimization of the operating algorithm, changes in the construction of the entire circuit and the location of its parts relative to each other help against internal interference.

What is considered very elegant is not the indiscriminate suppression of all interference, but the deliberate direction of them to those places in the circuit where they will fade out without causing harm. In some cases, this path is much simpler, more compact and cheaper.

Assessing the probability of interference in circuits and ways to prevent them is not a simple task, requiring theoretical knowledge and practical experience. But nevertheless, we can firmly say that the probability of interference increases:

- with an increase in switched current or voltage in the circuit,

- with increasing sensitivity of parts of the circuit,

- with an increase in the performance of the used parts.

In order not to redo the finished structure due to frequent failures, it is better to familiarize yourself with the design at the design stage possible sources and interference propagation paths. Since about half of all manifestations of interference are associated with “bad” power supply, it is best to start designing a device by choosing a method for powering its parts.

Interference in power supply circuits.

Figure 2 shows a typical block diagram of an electronic device, which consists of a power source, control circuit, driver and actuator.

Most of the simplest robots from the series on this site are built according to this scheme.

Rice. 2. Joint power supply of the control and power parts.

In such circuits we can conditionally distinguish two parts: control and power. The control part consumes relatively little current and contains any control or computing circuits. The power section consumes significantly more current and includes an amplifier and termination load.

Let's look at each part of the circuit in more detail.

Rice. 2 a.

Power supply(Fig. 2 a.) can be “battery-powered” or mains transformer block nutrition. The power supply may also include a voltage stabilizer and a small filter.

Rice. 2 b.

Control circuit- this is part of the circuit (Fig. 2 b.), where any information is processed in accordance with the operation of the algorithm. Signals from external sources, for example, from some sensors, can also come here. The control circuit itself can be assembled using microcontrollers or other microcircuits, or using discrete elements.

Communication lines they simply connect the control circuit to the driver-executive device, that is, these are just wiring or tracks on a printed circuit board.

Rice. 2nd century

Actuator(Fig. 2 c.) is often a mechanism that converts electrical signal into mechanical work, such as an electric motor or electromagnet. That is, the actuator converts electricity into a different form of energy and usually consumes a relatively large current.

Rice. 2 years

Since the signal from the control circuit is very weak, so driver or amplifier(Fig. 2 d) is an integral part of many schemes. The driver can be made, for example, using only a transistor or a special chip, depending on the type of actuator.

As a rule, the main source of strong interference is the actuator. The interference that appears here, having passed through the driver, spreads further along the power bus (The interference in Fig. 2 is shown schematically by an orange arrow). And since the control circuit is powered from the same power source, there is a high probability that this interference will affect it as well. That is, for example, an interference that appears in the motor will pass through the driver and can lead to a failure in the control circuit.

IN simple circuits Sometimes it is enough to place a large capacitor of about 1000 μF and a ceramic capacitor of 0.1 μF in parallel with the power source. They will act as a simple filter. In circuits with consumption currents of about 1 ampere or more, to protect against strong interference of complex shapes, you will have to install a bulky, complex filter, but this does not always help.

In many circuits, the easiest way to get rid of the effects of interference is to use separate power supplies for the control and power parts of the circuit, that is, the use of the so-called separate power supply.

Although separate power supply is used not only to combat interference.

Separate meals.

In Fig. Figure 3 shows a block diagram of a certain device. This circuit uses two power supplies. The power part of the circuit is powered from power supply 1, and the control circuit is from power supply 2. Both power sources are connected by one of the poles; this wire is common to the entire circuit and signals are transmitted relative to it along the communication line.

Rice. 3. Separate power supply for the control and power parts.

At first glance, such a circuit with two power supplies looks cumbersome and complex. In fact, such separate power supply circuits are used, for example, in 95% of all household equipment. Separate power supplies there are just different windings of transformers with different voltages and currents. This is another advantage of separate power supply circuits: several units with different supply voltages can be used in one device. For example, use 5 volts for the controller, and 10-15 volts for the motor.

If you look closely at the diagram in Fig. 3, it is clear that interference from the power part does not have the opportunity to get into the control part via the power line. Consequently, the need to suppress or filter it completely disappears.

Rice. 4. Separate power supply with stabilizer.

In mobile structures, for example, mobile robots, due to their size, it is not always convenient to use two battery packs. Therefore, separate power supply can be built using one battery pack. The control circuit will be powered from the main power source through a stabilizer with a low-power filter, Fig. 4. In this circuit, you need to take into account the voltage drop across the stabilizer of the selected type. Typically a battery pack with a higher voltage than the voltage required for the control circuit is used. In this case, the functionality of the circuit is maintained even when the batteries are partially discharged.

Rice. 5. L293 with separate power supply.

Many driver chips are specifically designed for use in circuits with separate power supply. For example, the well-known L293 driver chip ( Rice. 5) has a conclusion Vss- for powering the control circuit (Logic Supply Voltage) and output Vs- to power the final stages of the power driver (Supply Voltage or Output Supply Voltage).

In all robot designs with a microcontroller or a logic chip from the series, L293 can be switched on with a separate power supply circuit. In this case, the power supply voltage (voltage for the motors) can be in the range from 4.5 to 36 volts, and the voltage on Vss can be supplied the same as to power the microcontroller or logic chip (usually 5 volts).

If the power supply to the control part (microcontroller or logic chip) occurs through a stabilizer, and the power supply to the power part is taken directly from the battery pack, then this can significantly save energy losses. Since the stabilizer will only power the control circuit, and not the entire structure. This - Another advantage of separate power supply: energy saving.

If you look again at the diagram in Figure 3, you will notice that in addition to the common wire (GND), the power section is also connected to the control circuit by communication lines. In some cases, these wires can also carry interference from the power part into the control circuit. In addition, these communication lines are often highly susceptible to electromagnetic influences (“noise”). You can get rid of these harmful phenomena once and for all by using the so-called galvanic isolation.

Although galvanic isolation is also used not only to combat interference.

Galvanic isolation.

At first glance, this definition may seem incredible!

How can a signal be transmitted without electrical contact?

In fact, there are even two ways that allow this.

Rice. 6.

Optical signal transmission method based on the phenomenon of photosensitivity of semiconductors. For this, a pair of an LED and a photosensitive device (phototransistor, photodiode) is used, Fig. 6.

Rice. 7.

The LED-photodetector pair is located in isolation in one housing opposite each other. This is what this detail is called. optocoupler(foreign name optocopler), Fig. 7.

If current is passed through the optocoupler LED, the resistance of the built-in photodetector will change. This is how contactless signal transmission occurs, since the LED is completely isolated from the photodetector.

Each signal transmission line requires a separate optocoupler. The frequency of the optically transmitted signal can range from zero to several tens to hundreds of kilohertz.

Rice. 8.

Inductive signal transmission method is based on the phenomenon of electromagnetic induction in a transformer. When the current changes in one of the windings of the transformer, the current in its other winding changes. Thus, the signal is transmitted from the first winding to the second (Fig. 8). This connection between the windings is also called transformer, and a transformer for galvanic isolation is sometimes called isolation transformer.

Rice. 9.

Structurally, transformers are usually made on a ring ferrite core, and the windings contain several tens of turns of wire (Fig. 9). Despite the apparent complexity of such a transformer, you can make it yourself in a few minutes. Ready-made small-sized transformers for galvanic isolation are also sold.

Each signal transmission line requires a separate such transformer. The frequency of the transmitted signal can range from several tens of hertz to hundreds of thousands of megahertz.

Depending on the type of signal being transmitted and the circuit requirements, you can choose either transformer or optical galvanic isolation. In circuits with galvanic isolation, special converters are often installed on both sides to coordinate (connect, interface) with the rest of the circuit.

Let us now consider the block diagram using galvanic isolation between the control and power parts in Figure 10.

Rice. 10. Separate power supply and galvanic isolation of the communication channel.

From this diagram it can be seen that any interference from the power part has no way of penetrating into the control part, since there is no electrical contact between the parts of the circuit.

The absence of electrical contact between parts of the circuit in the case of galvanic isolation allows you to safely control actuators with high voltage power. For example, a control panel powered by a few volts can be galvanically isolated from a phase network voltage of several hundred volts, which increases safety for operating personnel. This is an important advantage of galvanic isolation circuits.

Control circuits with galvanic isolation can almost always be found in critical devices, as well as in pulsed power supplies. Especially where there is even the slightest chance of interference. But even in amateur devices, galvanic isolation is used. Since a slight complication of the circuit by galvanic isolation brings complete confidence in the uninterrupted operation of the device.

This article will primarily focus on optical isolation. analog signal. A budget option will be considered. Also, the main attention is paid to the speed of the circuit solution.

Methods for decoupling an analog signal

A short review. There are three main methods of galvanic isolation of an analog signal: transformer, optical and capacitor. The first two have found the greatest application. Today there is a whole class of devices called isolating amplifiers or isolating amplifiers (Isolated Amplifier). Such devices transmit a signal by means of its conversion (the circuit contains a modulator and a signal demodulator).

Fig.1. General circuit of isolating amplifiers.

There are devices both for transmitting an analog voltage signal (ADUM3190, ACPL-C87) and specialized ones for connecting directly to a current shunt (SI8920, ACPL-C79, AMC1200). In this article we will not consider expensive devices, however, we list some of them: iso100, iso124, ad202..ad215, etc.

There is also another class of devices - decoupling optical amplifiers with linearizing feedback(Linear Optocoupler) these devices include il300, loc110, hcnr201. The operating principle of these devices is easy to understand by looking at their typical connection diagram.

Fig.2. Typical scheme for isolating optical amplifiers.

You can read more about isolation amplifiers: A. J. Peyton, W. Walsh “Analog Electronics on Op-amps” (Chapter 2), the document AN614 “A Simple Alternative To Analog Isolation Amplifiers” from silicon labs will also be useful, there is a good one there comparison table. Both sources are available on the Internet.

Special optical signal isolation microcircuits

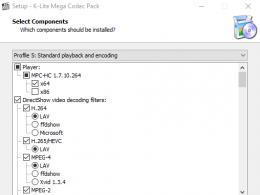

Now to the point! First, let's compare three specialized microcircuits: il300, loc110, hcnr201. Connected according to the same circuit:

Fig.3. Test circuit for il300, hcnr201 and loc110.

The only difference is in the ratings for il300, hcnr201 R1,R3=30k, R2=100R, and for loc110 10k and 200R respectively (I selected different ratings to achieve maximum performance, but not go beyond permissible limits, for example, by the current of the emitting diode). Below are oscillograms that speak for themselves (hereinafter: blue - input signal, yellow - output signal).

Fig.4. Oscillogram of il300 transient process.

Fig.5. Transient waveform hcnr201.

Fig.6. Transient waveformloc110.

Now consider the ACPL-C87B chip (range input signal 0..2V). To be honest, I spent quite a long time with her. I had two microcircuits in stock, after I got an unexpected result on the first one, I handled the second one very carefully, especially when soldering. I assembled everything according to the scheme indicated in the documentation:

Fig.7. Typical diagram forACPL— C87 from the documentation.

The result is the same. I soldered ceramic capacitors directly near the power pins, changed the op-amp (of course, tested it on other circuits), reassembled the circuit, etc. Here's the rub: the output signal has significant fluctuations.

Fig.8. Transient waveformACPL— C87.

Despite the fact that the manufacturer promises a noise level of the output signal of 0.013 mVrms and for option “B” an accuracy of ±0.5%. What's the matter? There may be an error in the documentation, since 0.013 mVrms is hard to believe. Unclear. But let's look at the Test Conditions/Notes column opposite Vout Noise and at Fig. 12 of the documentation:

Fig.9. Dependence of the noise level on the magnitude of the input signal and the frequency of the output filter.

Here the picture becomes a little clearer. Apparently the manufacturer is telling us that we can suppress these noises through a low-pass filter. Well, thanks for the advice (ironic). Why did they turn all this out in such a cunning way? Most likely it’s clear why. Below are the graphs without and with the output RC filter (R=1k, C=10nF (τ=10µS))

Fig. 10. Transient waveformACPL— C87 without and with output filter.

Application of general purpose optocouplers for signal isolation

Now let's move on to the fun part. Below are the diagrams that I found on the Internet.

Fig. 11. Typical circuit for optical isolation of an analog signal using two optocouplers.

Fig. 12. Typical circuit for optical isolation of an analog signal using two optocouplers.

Fig. 13. Typical circuit for optical isolation of an analog signal using two optocouplers.

This solution has both advantages and disadvantages. The advantage is the higher insulation voltage; the disadvantage is that two microcircuits can differ significantly in parameters, so by the way it is recommended to use microcircuits from the same batch.

I assembled this circuit on a 6n136 chip:

Fig. 14. Oscillogram of the transient process of decoupling at 6N136.

It worked, but slowly. I tried to assemble it on other microcircuits (such as sfh615), it works, but it’s also slow. I needed it faster. In addition, the circuit often does not work due to self-oscillations that occur (in such cases they say the ACS is unstable))) Increasing the value of capacitor C2, Fig., helps. 16.

One friend recommended a domestic optocoupler AOD130A. The result is obvious:

Fig. 15. Oscillogram of the transient decoupling process on the AOD130A.

And here is the diagram:

Fig. 16: Isolation diagram for AOD130A.

One potentiometer is needed (RV1 or RV2), depending on whether the output signal is less or greater than the input signal. In principle, it was possible to put only one RV=2k in series with R3=4.7k, or even leave only RV2=10k without R3. The principle is clear: be able to adjust around 5k.

Transformer signal decoupling chip

Let's move on to the transformer option. The ADUM3190 microcircuit is available in two versions for 200 and 400 kHz (I have the ADUM3190TRQZ for 400), there is also a microcircuit for a higher insulation voltage ADUM4190. Note that the case is the smallest of all – QSOP16. Output voltage Eaout from 0.4 to 2.4V. In my microcircuit output voltage the offset is about 100 mV (visible in the oscillogram in Fig. 18). Overall it works well, but personally I am not entirely satisfied with the output voltage range. Assembled according to the diagram from the documentation:

Fig. 17. ADUM3190 circuit from the documentation.

Some oscillograms:

Fig. 18. ADUM3190 transient waveform.

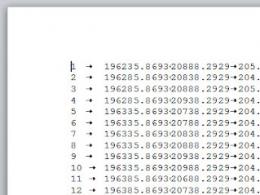

Results

Summarize. In my opinion the best option is the circuit for domestic ADO130A (where did they get them?!). And finally, a small comparison table:

| Chip | tr+delay (oscillation), µs | tf+delay (oscillation), µs | Range voltage, V | Voltage insulation, V | Noise (oscillatory) mVp-p. | Price** per piece, r (05.2018) |

|---|---|---|---|---|---|---|

| IL300 | 10 | 15 | 0-3* | 4400 | 20 | 150 |

| HCNR201 | 15 | 15 | 0-3* | 1414 | 25 | 150 |

| LOC110 | 4 | 6 | 0-3* | 3750 | 15 | 150 |

| ACPL-C87B | 15 | 15 | 0-2 | 1230 | nd | 500 |

| 6N136 | 10 | 8 | 0-3* | 2500 | 15 | 50 |

| AOD130A | 2 | 3 | 0.01-3* | 1500 | 10 | 90 |

| ADUM3190T | 2 | 2 | 0.4-2.4 | 2500 | 20 | 210 |

*- approximately (according to assembled circuit with performance optimization)

**- the price is average according to the minimum.

Yaroslav Vlasov

P.S. AOD130A produced by Proton OJSC (with their logo engraved in a black case) is good. The old ones (from the 90s in a brown case) are not suitable.

Introduction

Galvanic isolation (isolation), commonly referred to simply as decoupling, is a method by which individual parts of an electrical system can be at different ground potentials. The two most common reasons for creating decoupling are for safety from faults in industrial-grade products, and where wired communication is required between devices, each of which has its own power supply.

Power decoupling methods

Transformers

The most common form of decoupling is the use of a transformer. When designing a power stabilization circuit where decoupling is required, the isolating part of the design is associated with the need to increase/decrease the voltage level and is not considered as a separate part of the system. In the event that it is necessary to isolate the entire electrical system (for example, many automotive test equipment requires power supplies to be isolated from the AC mains), a 1:1 transformer can be installed in series with the system to provide the necessary isolation.

Figure 1 - Assortment of SMD transformers

Capacitors

A less common method of creating decoupling is to use capacitors in series. Due to the possibility of AC signals flowing through capacitors, this method may be effective way insulating parts of the electrical system from the alternating current network. This method is less reliable than the transformer method because if a fault occurs, the transformer breaks the circuit and shorts the capacitor. One of the purposes of creating galvanic isolation from the AC mains is to ensure that in the event of a fault, the user is safe from a functioning unlimited current source.

Figure 2 - Example of using capacitors to create decoupling

Signal Isolation Methods

Opto-isolators

When a signal is required to pass between two parts of a circuit at different ground potentials, a popular solution is an opto-isolator (optocoupler). The opto-isolator is a phototransistor that opens (“turns on”) when the internal LED is energized. The light emitted by the internal LED is the signal path and thus the isolation between ground potentials is not broken.

Figure 3 - Diagram of a typical opto-isolatorHall Sensor

Another method of transmitting information between electrical systems with separate ground potentials is the use of a sensor based on the Hall effect. The Hall sensor detects induction non-invasively and does not require direct contact with the signal of interest and does not violate the insulating barrier. The most common use of passing inductive information through circuits at different ground potentials is in current sensors.

Figure 4 - Current sensor used to measure current through a conductor

Conclusion

Galvanic isolation (isolation) is the separation of electrical systems/subsystems in which no D.C., and which may have different ground potentials. Isolation can be divided into main categories: power and signal. There are several ways to achieve decoupling, and depending on the project requirements, some methods may be preferable to others.

Case Study

Figure 5 - PoE (Power over Ethernet) project diagram based on the TPS23753PW controller

Figure 5 - PoE (Power over Ethernet) project diagram based on the TPS23753PW controller In the diagram above, several transformers and an opto-isolator are used to create a switching power supply, which is used in Ethernet devices PD (Powered Device, powered device). Connector J2 has internal magnets that isolate the entire system from the PoE source. T1 and U2 isolate the power supply (to the left of the red line) from the regulated 3.3V output (to the right of the red line).

In this article I will talk about how to literally make a simple galvanic isolation from a 220 V network from an old UPS (or rather, two) literally on your knees.

I hope it’s no secret to anyone why galvanic isolation from the network is needed. Many people probably know one of the most simple ways blow up half the circuit with a grounded oscilloscope. Therefore, I seriously thought about decoupling precisely after purchasing an oscilloscope. In the very simple case the decoupler looks like a transformer with a transformation ratio of 1:1. Therefore, initially the idea was to take some TS-270 and rewind it. But I didn’t want to do rewinding, and I didn’t have an extra transformer of sufficient power at hand. But somehow at work I came across an old UPS. Something like this:

And then the idea came to mind to make a denouement on “reversals”, i.e. when two identical transformers are switched on in mirror manner:

Naturally, the higher the voltage at the output of the transformers, the less current flows and the better, but I didn’t have to choose and I used the “as is” principle. It was decided to use the UPS case and the transformer that was already installed there. To control the presence of voltage at the output, the Chinese had:

After the second transformer was found and secured, all that remained was to connect everything.

As a result, we have the final diagram according to which we connect the transformers:

Fragment excluded. Our magazine exists on donations from readers. The full version of this article is available only

And we get something like this:

At first I threw away the original board, but, as it turned out, the case was losing its rigidity greatly and I had to return it to its place, having first desoldered all the parts:

Then I installed a voltmeter:

I used the 18 V secondary winding to power the backlight of the standard switch. I used a standard reusable UPS fuse as an input fuse, and a regular fuse holder was embedded to protect the output.

And, voila! Our solution is at work.

International Rectifier, a designer and manufacturer of power electronics since 1947, produces a huge range of opto-relays for all kinds of applications. The most popular of them can be divided into the following groups:

- Fast acting (PVA, PVD, PVR);

- General purpose (PVT);

- Low voltage medium power (PVG, PVN);

- High voltage powerful (PVX).

PVA33: fast acting relay

for signal switching

AC Relay Series PVA33— single pole, normally open. Designed for general analog signal switching purposes.

The operating principle of the device is as follows (Fig. 1). The voltage applied to the relay input causes current to flow through the gallium arsenide LED (GaAlAs), resulting in an intense glow of the latter. The light flux hits an integrated photovoltaic generator (IGG), which creates a potential difference between the gate and the source of the output switch, thereby transferring the latter to a conducting state. Power MOSFET transistors (HEXFET - patented IR technology) are used as power output switches. In this way, complete galvanic isolation of the input circuits from the output circuits is achieved.

Rice. 1.

The advantages of such a solution compared to conventional electromechanical and reed relays are a significant increase in service life and speed, reduction in power losses, and minimization of size. These advantages make it possible to improve the quality of products developed for various applications, for example, in the field of signal multiplexing, automatic test equipment, data acquisition systems and others.

The voltage level that the relays of this series are capable of switching lies in the range from 0 to 300 V (amplitude value) of both alternating and direct current. Wherein minimum level is determined (at constant current) by the channel resistance of the output transistors, which averages about 1 Ohm (maximum up to 20 Ohms).

The dynamic characteristics of the device are determined by the on-off time, which is about 100 μs. Thus, the guaranteed relay switching frequency can reach 500 Hz or more.

The maximum frequency of the switched signal depends mainly on frequency characteristics transistors used and for MOS switches reaches hundreds of kilohertz. The relays are supplied in 8-pin DIP packages and are available in two versions: through-hole and surface mount.

PVT312: telecommunication relay

general purpose

Photoelectric relay PVT312, single-pole, normally open, can be used on both direct and alternating current.

This solid state relay is specially designed for use in telecommunication systems. Relay series PVT312L(suffixed with "L") use active current limiting circuitry, which allows them to withstand transient current surges. PVT312 is available in a 6-pin DIP package.

Application: telecommunication keys, triggers, general schemes switching

Connection diagrams can be of three types (Fig. 2). In the first case, two chip keys are connected in series. Due to the symmetry, this allows the resulting circuit to switch alternating voltage. This type of circuit is called a type “A” connection. Type “B” differs in that only one of the two chip keys is used. This allows you to switch a larger, but only direct current. In the third option (type “C”), the keys are connected in parallel, thereby increasing the maximum possible current value.

Rice. 2.

PVG612: low voltage medium voltage relay

power for AC

Photoelectric Relay Series PVG612 - unipolar, normally open solid state relays. The compact devices of the PVG612 series are used for isolated switching of currents up to 1 A with voltages from 12 to 48 V AC or DC.

Relays of this type are interesting in that they are capable of switching relatively large (for of this type devices) alternating currents, while maintaining the speed inherent in MOS transistor solutions.

PVDZ172N: low voltage medium

power for DC

Relays of this series (Fig. 3), unlike those described above, are designed for switching currents only of constant polarity with a power of up to 1.5 A and a voltage of up to 60 V. For example, these relays are used in control lighting fixtures, motors, heating elements, etc.

Rice. 3.

PVDZ172N Available in normally open, single-pole design in 8-pin DIP packages.

Other possible applications: audio equipment, power supplies, computers and peripherals.

PVX6012: for heavy loads

For large low frequency loads, IR offers photoelectric relay PVX6012(Fig. 4) (single-pole, normally open). The device uses an output switch based on an insulated gate bipolar transistor (IGBT), which makes it possible to obtain a low voltage drop in the on-state and low loss currents in the closed state at sufficiently high speed operation (7 ms - on/1ms - off).

Rice. 4.

The PVX6012 is available in a 14-pin DIP package, which, interestingly, uses only four pins - this solution allows for better cooling of the device.

Main applications include: test equipment; industrial control and automation; replacement of electromechanical relays; replacement of mercury relays.

PVI: photo insulator for external

high power keys

Devices in this series are not relays in the proper sense of the word. That is, they are not able to commute large energy flows with the help of small ones. They only provide galvanic isolation of the input from the output, hence their name - photoelectric insulator (Fig. 5).

Rice. 5.

Why is such a “underreliance” necessary? The fact is that the PVI series devices produce an electrically isolated constant pressure, which is sufficient to directly drive the gates of high-power MOSFETs and IGBTs. In fact, this is an opto-relay, but without an output switch, for which the developer can use a separate transistor suitable for its power.

PVIs are ideal for applications requiring high current and/or high voltage switching with optical isolation between the control circuit and powerful circuits loads.

In addition, the series insulator PVI1050N contains two simultaneously controlled outputs, which makes it possible to connect them in series or in parallel to provide a higher control current (MOC) or a higher control voltage (IGT). Thus, in fact, you can get an output signal of 10 V/5 μA when connected in series and 5 V/10 μA when connected in parallel.

The two outputs of the PVI1050N can be used separately, provided that the potential difference between the outputs does not exceed 1200 VDC. The input-output isolation is 2500 VDC.

Devices of this series are produced in 8-pin DIP packages and are used in organizing the control of powerful loads, voltage converters, etc.

PVR13: double fast acting relay

The main feature of this series is the presence of two independent relays in one housing (Fig. 6), each of which can be connected as type “A”, “B”, or “C” (for an explanation of the types, see above in the description of PVT312). Maximum switching voltage 100 V (DC/AC), current 300 mA. Otherwise, this relay is close in scope and characteristics to the PVA33 and is also intended for switching analog signals of medium frequency (up to hundreds of kilohertz).

Rice. 6.

Available in 16-pin DIP packages with pins for through-hole mounting.

The main characteristics of IR optoelectronic relays are presented in Table 1.

Table 1. Parameters of IR optoelectronic relays

| Characteristics | PVA33 | PVT312 | PVG612N | PVDZ172N | PVX6012 |

|---|---|---|---|---|---|

| Input characteristics | |||||

| Minimum control current, mA | 1…2 | 2 | 10 | 10 | 5 |

| Max. control current to be in closed state, mA | 0,01 | 0,4 | 0,4 | 0,4 | 0,4 |

| Control current range (current limitation required!), mA | 5…25 | 2…25 | 5…25 | 5…25 | 5…25 |

| Maximum reverse voltage, IN | 6 | 6 | 6 | 6 | 6 |

| Output characteristics | |||||

| Operating voltage range, V | 0…300 | 0…250 | 0…60 | 0…60 (constant) | 280 (AC)/400 (DC) |

| Maximum continuous load current at 40°C, A | 0,15 | - | - | 1,5 | 1 |

| A conn. (post or variable) | - | 0,19 | 1 | - | - |

| In connection (fast.) | - | 0,21 | 1,5 | - | - |

| With connection (fast.) | - | 0,32 | 2 | - | - |

| Maximum pulse current, A | - | - | 2,4 | 4 | not a repeat. 5 A (1 sec) |

| Resistance in open state, no more, Ohm | 24 | - | - | 0,25 | - |

| A conn. | - | 10 | 0,5 | - | - |

| In connection | - | 5,5 | 0,25 | - | - |

| With connection | - | 3 | 0,15 | - | - |

| Resistance in closed state, not less, MOhm | 10000 | - | 100 | 100 | - |

| Turn-on time, no more. ms | 0,1 | 3 | 2 | 2 | 7 |

| Shutdown time, no more, ms | 0,11 | 0,5 | 0,5 | 0,5 | 1 |

| Output capacitance, no more, pF | 6 | 50 | 130 | 150 | 50 |

| Voltage rise rate, not less, V/µs | 1000 | - | - | - | - |

| Other | |||||

| Electric strength of insulation “input-output”, V (SCR) | 4000 | 4000 | 4000 | 4000 | 3750 |

| Insulation resistance, input-output, 90 V DC, ohms | 1012 | 1012 | 1012 | 1012 | 1012 |

| Input-output capacitance, pF | 1 | 1 | 1 | 1 | 1 |

| Maximum contact soldering temperature, °C | 260 | 260 | 260 | 260 | 260 |

| Operating temperature, °C | -40…85 | -40…85 | -40…85 | -40…85 | -40…85 |

| Storage temperature, °C | -40…100 | -40…100 | -40…100 |

-40…100 | -40…100 |

Application of Optoelectronic Relays IR

Control systems. In the interfaces of the automated control system of one of current problems is the organization of communication between the control and switched circuits, ensuring reliable galvanic isolation. That is, it is necessary to organize the transmission of information (for example, a signal to an actuator) without electrical contact. One of the first devices of this kind were electromechanical relays, in which information was transmitted via a magnetic field. However, the presence of mechanical parts led to sparking contacts and low performance of such systems.

The use of signal transmission through a light flux (optoelectronic relays) in automated control system interfaces (Fig. 7) compared to electromechanical switches provides higher reliability, switching speed, durability, and better weight and size indicators; and the advantage in comparison with electronic switches is the absence of a common point and mutual influence of circuits during switching.

Rice. 7.

The presence of galvanic isolation in the control system is one of the important properties of the switch, because allows you to create separate control flows, which, in turn, makes it possible to ensure electrical independence of the information and executive zones of the system. Optical galvanic isolation isolates microelectronic control equipment from high-current and high-voltage circuits of peripheral execution devices, which leads to increased noise immunity, service life and reduced price of such equipment.

Rice. 8.

Another necessary function in measuring equipment is switching operating modes (measuring range, gain, type of connection, etc.), which was previously performed mechanically. For example, to measure voltage, a voltmeter is connected to the circuit in parallel, while to measure current, you need serial connection measuring equipment with circuit. In some instruments, to implement such a switch, it was necessary to use another input, mechanically switching the measuring line. This is quite inconvenient in the case of frequent changes in the measured parameter, so the use of optoelectronic relays can effectively solve this problem, significantly increasing the ease of use of the device.

On the other hand, in data acquisition systems the need to use opto-relays is often due to the high probability of damage to the sensitive input circuits of the measuring equipment (analog-to-digital and frequency converters). Such an undesirable effect may arise, for example, due to the long length of the conductors from the primary transducer to the measuring element, which contributes to the induction of electrostatic interference. In addition, both transient processes during switching on/off of the equipment and errors in its use, for example, the presence of a large amplitude input signal during a power outage, can have a significant impact.

All these factors lead to the need to use galvanic isolation. An example is the PVT312L series relay with a built-in active ripple current suppression circuit, which can be effectively used in devices associated with long conductors or operating in difficult electromagnetic conditions (wired environmental monitoring systems of enterprises, industrial measuring transducers).

Telecommunications. The use of opto-relays in the field of communications is also a promising area. There are a few unique features, for the implementation of which the advantages of opto-relays can be effectively used. This includes galvanic isolation between the modem and the telephone line to prevent damage associated with electrostatic (including lightning) discharges; implementation of specific functions of telephone equipment (pulse and tone dialing, connection and determination of line status), etc.

Conclusion

In recent years, there has been a trend towards a constant increase in demand for optoelectronic relays from IR. The main consumers of solid-state relays are the industrial giants of our country - instrument-making and transport enterprises, large state corporations Rostelecom, Rosatom, Russian Railways. Manufacturers value convenience and high specifications IR relays for industrial applications.

On the other hand, the requirements for the reliability of electronic equipment from the military and aerospace industries are constantly growing. The issue is very relevant, which requires specific technical solutions that will reduce equipment failures during operation. None of the experts doubt that solid-state relays can increase the reliability of special-purpose equipment.