Measuring transducers. Parametric measuring transducers

The most important metrological characteristics of converters are: nominal static conversion characteristic, sensitivity, basic error, additional errors, or influence functions, output signal variation, output impedance, dynamic characteristics, etc.

The most important non-metrological characteristics include dimensions, weight, ease of installation and maintenance, explosion safety, resistance to mechanical, thermal, electrical and other overloads, reliability, cost of manufacture and operation, etc.

Depending on the type of output signal, all measuring transducers are divided into parametric and generator. They are also classified according to the principle of action. Only the transmitters that have received the most use are discussed below.

13.1 Parametric transducers

General information. In parametric converters, the output value is the parameter electrical circuit (R, L, M, C). When using parametric transducers, an additional power source is required, the energy of which is used to form the output signal of the transducer.

Rheostat converters. Rheostatic transducers are based on change electrical resistance conductor under the influence of the input value - displacement. A rheostat transducer is a rheostat whose brush (moving contact) moves under the influence of a measured non-electric quantity. On fig. 11-5 schematically shows some designs of rheostat converters for angular (Fig. 11-5, a) and linear (Fig. 11-5, b and c) movements. The converter consists of a winding applied to the frame and a brush. For the manufacture of frames, dielectrics and metals are used. The winding wire is made of alloys (an alloy of platinum with iridium, constantan, nichrome and fechral). For winding, insulated wire is usually used. After the winding is made, the wire insulation is cleaned off at the points of contact with the brush. The transducer brush is made either from wires or from flat springy strips, and both pure metals (platinum, silver) and alloys (platinum with iridium, phosphor bronze, etc.) are used.

Rice. 11-5. Rheostat transducers for angular (a), linear (b) displacements and for the functional transformation of linear displacements (c)

The dimensions of the converter are determined by the value of the measured displacement, the resistance of the winding and the power released in the winding.

To obtain a nonlinear transformation function, functional rheostat converters are used. The desired character of the transformation is often achieved by profiling the frame of the converter (Fig. 11-5, v).

In the rheostatic converters under consideration, the static conversion characteristic has a stepped character, since the resistance changes in jumps, equal to resistance one turn, which causes an error. Sometimes rheochord transducers are used, in which the brush slides along the axis of the wire. These transducers do not have the specified error. Rheostatic transducers are included in measuring circuits in the form of balanced and non-equilibrium bridges, voltage dividers, etc.

The advantages of converters include the possibility of obtaining high precision conversions that are significant in terms of the level of output signals and relative simplicity designs. Disadvantages - the presence of a sliding contact, the need for relatively large movements, and sometimes significant effort to move.

Rheostatic transducers are used to convert relatively large displacements and other non-electric quantities (forces, pressures, etc.) that can be converted into displacement.

Strain sensitive transducers (sensors). The operation of the converters is based on the tensor effect, which consists in changing the active resistance of the conductor (semiconductor) under the action of the mechanical stress and deformation caused in it.

Rice. 11-6. Strain gauge wire transducer

If the wire is subjected to mechanical stress, such as stretching, then its resistance will change. The change in the resistance of the wire under mechanical action on it is explained by a change in the geometric dimensions (length, diameter) and the resistivity of the material.

Strain-sensitive transducers, widely used at present (Fig. 11-6), are a thin zigzag laid and glued to a strip of paper (substrate /) wire 2 (wire grate). The converter is connected to the circuit using welded or soldered leads 3. The transducer is glued to the surface of the part under study so that the direction of the expected deformation coincides with the longitudinal axis of the wire grating.

For the manufacture of transducers, mainly constantan wire with a diameter of 0.02-0.05 mm is used. (S== 1.9 - 2.1). Constantan has a low temperature coefficient of electrical resistance, which is very important, since the change in the resistance of transducers during deformations, for example, of steel parts is commensurate with the change in the resistance of the transducer with temperature changes. As a substrate, thin (0.03-0.05 mm) paper is used, as well as a film of varnish or glue, and at high temperatures, a layer of cement.

Foil transducers are also used, in which foil and film strain gauges are used instead of wire, obtained by sublimation of a strain-sensitive material with its subsequent deposition on a substrate.

Adhesives are used to glue the wire to the substrate and the entire transducer to the part (celluloid solution in acetone, BF-2, BF-4 glue, bakelite, etc.). For high temperatures (above 200 °C), heat-resistant cements, silicone varnishes and adhesives, etc. are used.

Converters are available in different sizes depending on the purpose. Most often, transducers with a grating length (base) from 5 to 50 mm are used, having a resistance of 30-500 ohms.

A change in temperature causes a change in the transformation characteristics of strain gauges, which is explained by the temperature dependence of the resistance of the transducer and the difference in the temperature coefficients of linear expansion of the material of the strain gauge and the part under study. The effect of temperature is usually eliminated by applying appropriate temperature compensation methods.

A pasted strain gauge transducer cannot be removed from one part and pasted onto another. Therefore, to determine the characteristics of the transformation (coefficient S), one resorts to selective calibration of the converters, which gives the value of the coefficient S with an error of ±1%. Methods for determining the characteristics of strain gauges are regulated by the standard. Advantages of these converters - linearity static characteristic transformations, small dimensions and weight, simplicity of design. Their disadvantage is their low sensitivity.

In those cases where high sensitivity is required, strain-sensitive transducers made in the form of strips of semiconductor material are used. The coefficient S for such converters reaches several hundred. However, the reproducibility of the characteristics of semiconductor converters is poor. At present, integrated semiconductor strain gauges are mass-produced, forming a bridge or half-bridge with thermal compensation elements.

Equilibrium and non-equilibrium bridges are used as measuring circuits for strain gauges. Strain gauges are used to measure deformations and other non-electrical quantities: forces, pressures, moments, etc.

Thermally sensitive transducers (thermistors). The principle of operation of the converters is based on the dependence of the electrical resistance of conductors or semiconductors on temperature.

Heat exchange takes place between the thermistor and the investigated medium during the measurement process. Since the thermistor is included in the electrical circuit, with the help of which its resistance is measured, a current flows through it, releasing heat in it. The heat exchange of the thermistor with the medium occurs due to the thermal conductivity of the medium and convection in it, the thermal conductivity of the thermistor itself and the fittings to which it is attached, and, finally, due to radiation. The intensity of heat transfer, and hence the temperature of the thermistor, depends on its geometric dimensions and shape, on the design of protective fittings, on the composition, density, thermal conductivity, viscosity and other physical properties of the gas or liquid medium surrounding the thermistor, as well as on the temperature and speed of movement of the medium .

Rice. 11-7. Device(s) and appearance fittings (b) platinum thermistor

Thus, the dependence of temperature, and hence the thermistor resistance, on the factors listed above can be used to measure various non-electric quantities characterizing a gas or liquid medium. When designing the transducer, the aim is to ensure that the heat exchange of the thermistor with the medium is mainly determined by the measured non-electric quantity.

According to the mode of operation, thermistors are overheated and without deliberate overheating. In converters without overheating, the current passing through the thermistor practically does not cause overheating, and the temperature of the latter is determined by the temperature of the medium; these transducers are used to measure temperature. In overheating converters, electric current causes overheating, depending on the properties of the medium. Overheating transducers are used to measure speed, density, composition of the medium, etc. Since overheating thermistors are affected by the temperature of the medium, circuit methods are usually used to compensate for this effect.

To measure temperature, the most common thermistors are made of platinum or copper wire.

Standard platinum thermistors are used to measure temperature in the range from -260 to + 1100 ° C, copper - in the range from - 200 to + 200 ° C (GOST 6651-78). Low-temperature platinum thermistors (GOST 12877-76) are used to measure temperatures in the range from -261 to -183 °C.

On fig. 11-7, a The device of a platinum thermistor is shown. In the channels of the ceramic tube 2 there are two (or four) sections of the helix 3 made of platinum wire connected in series. Solder the leads to the ends of the spiral 4, used to include a thermistor in the measuring circuit. The fastening of the leads and the sealing of the ceramic tube are made with glaze /. The channels of the tube are covered with anhydrous aluminum oxide powder, which acts as an insulator and a retainer for the spiral. Anhydrous alumina powder, having high thermal conductivity and low heat capacity, provides good heat transfer and low inertia of the thermistor. To protect the thermistor from mechanical and chemical influences of the external environment, it is placed in protective fittings (Fig. 11-7, b) made of stainless steel.

The initial resistances (at 0 ° C) of platinum standard thermistors are 1, 5, 10, 46, 50, 100 and 500 Ohms, copper - 10, 50, 53 and 100 Ohms.

The permissible value of the current flowing through the thermistor when it is included in the measuring circuit must be such that the change in the resistance of the thermistor during heating does not exceed 0.1% of the initial resistance.

Static conversion characteristics in the form of tables (calibration) and permissible deviations of these characteristics for standard thermistors are given in GOST 6651-78.

In addition to platinum and copper, sometimes nickel is used to make thermistors.

To measure temperature, semiconductor thermistors (thermistors) of various types are also used, which are characterized by greater sensitivity (TCS thermistor-

the resistance is negative and at 20 °C is 10-15 times higher than the TCR of copper and platinum) and have higher resistances (up to 1 MΩ) at very small sizes. The disadvantage of thermistors is poor reproducibility and non-linearity of the conversion characteristic:

where rt and Ro- thermistor resistance at temperatures T and That; That- initial temperature of the operating range; V- coefficient.

Thermistors are used in the temperature range from -60 to + 120°C.

To measure temperatures from -80 to -f-150 ° C, thermal diodes and thermotransistors are used, in which resistance changes under the influence of temperature R- i-junction and voltage drop at this junction. The voltage sensitivity of the thermotransistor is 1.5-2.0 mV/K, which significantly exceeds the sensitivity of standard thermocouples (see Table 11-1). These converters are usually included in bridge circuits and circuits in the form of voltage dividers.

The advantages of thermal diodes and thermal transistors are high sensitivity, small size and low inertia, high reliability and low cost; disadvantages - a narrow temperature range and poor reproducibility of the static conversion characteristics. Influence last flaw reduced by the use of special chains.

The thermal inertia of standard thermistors according to GOST 6651-78 is characterized by an indicator of thermal inertia v^, defined as the time required for the temperature difference of the medium and any point of the converter introduced into it to become equal to 0.37 of that value when the converter is introduced into an environment with a constant temperature , which she had at the time of the onset of a regular thermal regime. The thermal inertia index is determined from that part of the transient thermal process curve of the converter, which corresponds to the regular mode, that is, it has an exponential character (in a semi-logarithmic scale - a straight line). The value of e^ for various types of standard transducers ranges from several tens of seconds to several minutes.

When fast-resistance thermistors are needed, very thin wire (microwire) is used for their manufacture, or small volume thermistors (bead) or thermotransistors are used.

Rice. 11-8. Gas analyzer converter based on the principle of thermal conductivity measurement

Rs. 11-9. Dependence of gas thermal conductivity on pressure

Thermistors are used in instruments for the analysis of gas mixtures. Many gas mixtures differ from each other and from air in thermal conductivity.

In devices for gas analysis - gas analyzers - an overheating platinum thermistor (Fig. 11-8) placed in a chamber is used to measure thermal conductivity 2 with the analyzed gas. The design of the thermistor, armature and chamber, as well as the value of the heating current, are chosen such that heat exchange with the medium is carried out mainly due to the thermal conductivity of the gaseous medium.

To eliminate the influence of external temperature, in addition to the operating temperature, a compensation chamber with a thermistor filled with a gas of constant composition is used. Both chambers are made in the form of a single block, which provides the chambers with the same temperature conditions. During measurements, the working and compensation thermistors are included in the adjacent arms of the bridge, which leads to compensation for the effect of temperature.

Thermistors are used in devices for measuring the degree of rarefaction. On fig. 11-9 shows the dependence of the thermal conductivity of the gas located between the bodies A and B, from his pressure.

Thus, the thermal conductivity of a gas becomes dependent on the number of molecules per unit volume, i.e., on pressure (degree of rarefaction). The dependence of the thermal conductivity of a gas on pressure is used in vacuum gauges - devices for measuring the degree of rarefaction.

To measure thermal conductivity in vacuum gauges, metal (platinum) and semiconductor thermistors are used, placed in a glass or metal container, which is connected to a controlled environment.

Thermistors are used in devices for measuring the speed of a gas flow - hot-wire anemometers. The steady state temperature of an overheating thermistor placed in the path of the gas flow depends on the flow rate. In this case, convection (forced) will be the main way of heat exchange between the thermistor and the medium. The change in the resistance of the thermistor due to the removal of heat from its surface by a moving medium is functionally related to the velocity of the medium.

The design and type of the thermistor, fittings and heating thermistor current are chosen such that all heat transfer paths are reduced or excluded, except for convective.

The advantages of hot-wire anemometers are high sensitivity and speed. These devices make it possible to measure speeds from 1 to 100-200 m/s using a measuring circuit, with the help of which the temperature of the thermistor is automatically maintained almost unchanged.

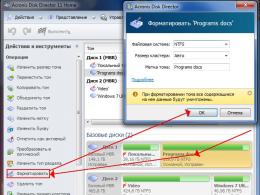

electrolytic converters. Electrolytic converters are based on the dependence of the electrical resistance of an electrolyte solution on its concentration. They are mainly used to measure the concentration of solutions.

On fig. 11-10, for example, graphs of the dependences of the electrical conductivity of some electrolyte solutions on concentration are shown With solute. It follows from this figure that, in a certain concentration range, the dependence of electrical conductivity on concentration is unambiguous and can be used to determine With.

Rice. 11-10. Dependence of the electrical conductivity of electrolyte solutions on the concentration of the dissolved substance

Rice. 11-11. Laboratory electrolytic converter

The transducer used in the laboratory to measure the concentration is a vessel with two electrodes (electrolytic cell) (Fig. 11-11). For industrial continuous measurements, the transducers are flow-through, and structures are often used in which the walls of the vessel (metal) play the role of the second electrode.

The electrical conductivity of solutions depends on temperature. Thus, when using electrolytic converters, it is necessary to eliminate the effect of temperature. This problem is solved by stabilizing the temperature of the solution using a refrigerator (heater) or by using temperature compensation circuits with copper thermistors, since the temperature coefficients of conductivity of copper and electrolyte solutions have opposite signs.

When a direct current passes through the converter, the electrolysis of the solution occurs, which leads to a distortion of the measurement results. Therefore, solution resistance measurements are usually carried out on alternating current (700-1000 Hz), most often using bridge circuits.

Inductive transducers. The principle of operation of the converters is based on the dependence of the inductance or mutual inductance of the windings on the magnetic circuit on the position, geometric dimensions and magnetic state of the elements of their magnetic circuit.

Rice. 11-12. Magnetic circuit with gaps and two windings

The inductance and mutual inductance can be changed by acting on the length b, the cross section of the air section of the magnetic circuit s, on the power losses in the magnetic circuit, and in other ways. This can be achieved, for example, by moving the movable core (armature) / (Fig. 11-12) relative to the fixed 2, the introduction of a non-magnetic metal plate 3 into the air gap, etc.

On fig. 11-13 schematically show various types of inductive transducers. An inductive transducer (Fig. 11-13, a) with a variable length of the air gap b is characterized by a non-linear dependence L=f(b). Such a converter is usually used when the armature moves by 0.01-5 mm. Significantly lower sensitivity, but linear dependence L=f(s) variable air gap transducers differ (Fig. 11-13, b). These converters are used for movements up to 10-15 mm.

Rice. 11-13. Inductive transducers with variable gap length (a), with variable gap section (b), differential (v), differential transformer (d), differential transformer with open magnetic circuit (e) magnetoelastic (e)

An armature in an inductive transducer experiences an (undesirable) force of attraction from an electromagnet

![]()

where Wm- energy of the magnetic field; L- converter inductance; / - current passing through the converter winding.

Widespread inductive differential converters (Fig. 11-13, v), in which, under the influence of the measured value, two gaps of electromagnets change simultaneously and, moreover, with different signs. Differential transducers in combination with an appropriate measuring circuit (usually a bridge) have a higher sensitivity, less non-linearity of the conversion characteristic, are less influenced by external factors and a reduced resultant force on the armature from the electromagnet than non-differential transducers.

On fig. 11-13, G shows the switching circuit of a differential inductive converter, whose output values are mutual inductances. Such converters are called mutually inductive or transformer. When the primary winding is powered by alternating current and with a symmetrical position of the armature relative to the electromagnets, the EMF at the output terminals is zero. When the armature is moved, an emf appears at the output terminals.

To convert relatively large displacements (up to 50-100 mm), transformer converters with an open magnetic circuit are used (Fig. 11-13, O).

Apply transformer converters of the angle of rotation, consisting of a fixed stator and a movable rotor with windings. The stator winding is fed with alternating current. Rotation of the rotor causes a change in the value and phase of the EMF induced in its winding. Such transducers are used for measuring large angular displacements.

Inductosins are used to measure small angular displacements (Fig. 11-14). Rotor / and stator 2 inductosyn is supplied with printed windings 3, looking like radial raster. The principle of action of inductosin is similar to that described above. By applying the windings in a printed way, it is possible to obtain a large number of pole winding pitches, which ensures high sensitivity of the converter to a change in the angle of rotation.

Rice. 11-14. Device (a) and type of printed winding (b) inductosyn

If the ferromagnetic core of the converter is subjected to mechanical stress F, then due to a change in the magnetic permeability of the core material, the magnetic resistance of the circuit will change, which will entail a change in the inductance L and mutual inductance M windings. Magnetoelastic transducers are based on this principle (Fig. 11-13, e).

The transducer design is determined by the range of measured displacement. Converter dimensions are selected based on the required output signal power.

To measure the output parameter of inductive converters, bridge (equilibrium and non-equilibrium) circuits, as well as a compensation (in automatic devices) circuit for differential transformer converters, are most widely used.

Inductive transducers are used to convert displacement and other non-electric quantities that can be converted into displacement (force, pressure, moment, etc.).

Compared to other displacement transducers, inductive transducers are distinguished by high power output signals, simplicity and reliability in operation.

Their disadvantage is the reverse effect of the transducer on the object under study (the effect of an electromagnet on the armature) and the effect of the armature inertia on frequency characteristics device.

Rice. 11-15. Capacitive transducers with a variable distance between the plates (a), differential (b), differential with a variable active area of the plates (c) and with a changing permittivity of the medium between the plates (d)

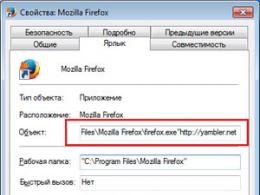

Capacitive converters. Capacitive transducers are based on the dependence of the electrical capacitance of the capacitor on the dimensions, the relative position of its plates and on the dielectric constant of the medium between them.

On fig. 11-15 schematically shows the arrangement of various capacitive transducers. The converter in fig. 11-15, a is a capacitor, one plate of which moves under the action of the measured value X relative to the fixed plate. The static characteristic of the transformation C(b) is non-linear. The sensitivity of the transducer increases with decreasing distance 6. Such transducers are used to measure small displacements (less than 1 mm).

A small working movement of the plates leads to an error from changing the distance between the plates with temperature fluctuations. By choosing the dimensions of the transducer parts and materials, this error is reduced.

In capacitive transducers, there is an (undesirable) force of attraction between the plates

![]()

where W 3- energy of the electric field; U and C are the voltage and capacitance between the plates, respectively.

Differential transducers are also used (Fig. 11-15, b), which have one movable and two fixed plates. When exposed to the measured value X these converters simultaneously change capacitances. On fig. 11-15, v shows a differential capacitive transducer with a variable active area of the plates. Such a transducer is used to measure relatively large linear (more than 1 mm) and angular displacements. In these transducers, it is easy to obtain the required conversion characteristic by profiling the plates.

Transducers (e) are used to measure the level of liquids, the humidity of substances, the thickness of dielectric products, etc. For example (Fig. 11-15, G) the device of the capacitive level gauge converter is given. The capacitance between the electrodes lowered into the vessel depends on the level of the liquid, since a change in the level leads to a change in the average permittivity of the medium between the electrodes. By changing the configuration of the plates, one can obtain the desired character of the dependence of the instrument readings on the volume (mass) of the liquid.

To measure the output parameter of capacitive transducers, bridge circuits and circuits using resonant circuits are used. The latter make it possible to create devices with high sensitivity, capable of responding to displacements of the order of 10~7 mm. Circuits with capacitive converters are usually fed with high frequency current (up to tens of megahertz), which is caused by the desire to increase the signal entering the measuring device, and the need to reduce the shunting effect of the insulation resistance.

ionization converters. The converters are based on the phenomenon of gas ionization or the luminescence of certain substances under the action of ionizing radiation.

If a chamber containing a gas is irradiated, for example, with p-rays, then a current will flow between the electrodes included in the electrical circuit (Fig. 11-16). This current depends on the voltage applied to the electrodes, on the density and composition of the gaseous medium, the size of the chamber and electrodes, the properties and intensity of ionizing radiation, etc. These dependencies are used to measure various non-electrical quantities: the density and composition of the gaseous medium, the geometric dimensions of parts and etc.

Rice. 11-16. Scheme of the ionization converter

Rice. 11-17. Volt-ampere characteristic of the ionization transducer

As ionizing agents, a-, p- and y-rays of radioactive substances are used, much less often - x-rays and neutron radiation.

To measure the degree of ionization, converters are used - ionization chambers and ionization counters, the operation of which corresponds to different sections of the current-voltage characteristic of the gas gap between two electrodes. On fig. 11-17 shows the dependence of the current in the chamber (Fig. 11-16) with a constant gas composition on the applied voltage U and radiation intensity. Location on A characteristics, the current increases in direct proportion to the voltage, then its growth slows down and in the area B reaches saturation. This indicates that all the ions generated in the chamber reach the electrodes. Location on V the ionization current begins to grow again, which is caused by secondary ionization when primary electrons and ions collide with neutral molecules. With a further increase in voltage (section G) ionization current ceases to depend on the initial ionization and comes

continuous discharge (section D) which is no longer dependent on exposure to radioactive radiation.

Plots A and B current-voltage characteristics describe the action of ionization chambers, and sections V and G - ionization counters. In addition to ionization chambers and counters, scintillation (luminescent) counters are used as ionization converters. The principle of operation of these counters is based on the occurrence in certain substances - phosphors (silver-activated zinc sulfide, cadmium sulfide, etc.) - under the influence of radioactive radiation of light flashes (scintillations), which are recorded in the counters by photomultipliers. The brightness of these flashes, and hence the current of the photomultiplier, are determined by radioactive radiation.

The choice of the type of ionization transducer depends largely on the ionizing radiation.

Alpha rays (the nuclei of the helium atom) have a high ionizing power, but have a low penetrating power. In solids, a-rays are absorbed in very thin layers (a few to tens of micrometers). Therefore, when using a-beams, the a-emitter is placed inside the transducer.

Beta rays are a stream of electrons (positrons); they have a much lower ionizing power than a-rays, but they have a higher penetrating power. The path length in solids reaches several millimeters. Therefore, the emitter can be located both inside and outside the converter.

A change in the distance between the electrodes, the area of overlap of the electrodes, or the position of the source of radioactive radiation relative to the ionization chambers or counters affects the value of the ionization current. Therefore, these dependencies are used to measure various mechanical and geometric quantities.

On fig. 11-18 as an example, an ionization membrane manometer is shown, where / is an emitter; 2 - membrane; 3 - fixed electrode isolated from the membrane. Between electrodes 2 a 3 a potential difference sufficient to achieve saturation current is applied. When the pressure changes R the membrane flexes, changing the distance between the electrodes and the value of the ionization current.

Rice. 11-18. Ionization diaphragm pressure gauge

Rice. 11-19. Gas discharge counter

Gamma rays are electromagnetic oscillations of a very small wavelength (10 ~ 8 -10 ~ "cm) that occur during radioactive transformations. Gamma rays have a high penetrating power.

The designs of ionization chambers and counters are varied and depend on the type of radiation.

To register individual particles, as well as to measure small y-radiations, so-called gas-discharge counters are widely used, the action of which is described by sections V and G current-voltage characteristics. The device of the gas-discharge counter is shown in fig. 11-19. The counter consists of a metal cylinder /, inside of which a thin tungsten wire is stretched 2. Both of these electrodes are placed in a glass cylinder. 3 s inert gas. When the gas is ionized, current pulses appear in the counter circuit, the number of which is counted.

As sources of a-, p- and y-radiation, radioactive isotopes are usually used. Radiation sources used in measuring technology must have a significant half-life and sufficient radiation energy (cobalt-60, strontium-90, plutonium-239, etc.).

The main advantage of devices using ionizing radiation is the possibility of non-contact measurements, which is of great importance, for example, when measuring in aggressive or explosive environments, as well as in environments under high pressure or high temperatures. The main drawback of these devices is the need to use biological protection at high activity of the radiation source.

13.2 Generator transducers

General information. V generator converters the output quantity is the EMF or charge, functionally related to the measured non-electric quantity.

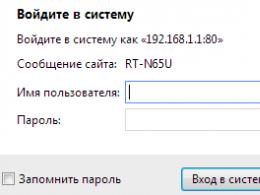

Thermoelectric converters. These converters are based on the thermoelectric effect that occurs in a thermocouple circuit.

With a temperature difference of points / and 2, the connection of two dissimilar conductors A and B(Fig. 11-20, a), forming a thermocouple, thermo-EMF arises in the thermocouple circuit.

To measure thermo-EMF, an electrical measuring device (millivoltmeter, compensator) is included in the thermocouple circuit (Fig. 11-20, b). The connection point of the conductors (electrodes) is called the working end of the thermocouple, the points 2 and 2" - free ends.

In order for the thermo-EMF in the thermocouple circuit to be unambiguously determined by the temperature of the working end, it is necessary to maintain the temperature of the free ends of the thermocouple the same and unchanged.

Rice. 11-20. Thermocouple (a) and the method of including the device in the thermocouple circuit (b)

The calibration of thermoelectric thermometers - devices that use thermocouples to measure temperature, is usually carried out at a temperature of the free ends of 0 ° C. Calibration tables for standard thermocouples are also compiled under the condition that the temperature of the free ends is equal to 0 °C. In the practical application of thermoelectric thermometers, the temperature of the free ends of the thermocouple is usually not equal to 0 °C and therefore a correction must be introduced.

For the manufacture of thermocouples currently used for temperature measurement, mainly special alloys are used.

To measure high temperatures, thermocouples of the TPP, TPR and TVR types are used. Thermocouples made of noble metals (TPP and TPR) are used in measurements with increased accuracy. In other cases, non-precious metal thermocouples (TXA, TXK) are used.

To protect against external influences (pressure, aggressive gases, etc.), thermocouple electrodes are placed in protective fittings, structurally similar to thermistor fittings (Fig. 11-7, b).

For the convenience of stabilizing the temperature of the free ends, sometimes the thermocouple is extended using the so-called extension wires made either from the corresponding thermoelectrode materials or from specially selected materials that are cheaper than the electrode ones and satisfy the condition of thermoelectric identity with the main thermocouple in the range of possible temperatures of the free ends ( usually from 0 to 100 °C). In other words, the extension wires must have the same temperature dependence of thermo-EMF in the specified temperature range as that of the main thermocouple.

The inertia of thermocouples is characterized by an indicator of thermal inertia. Designs of fast-response thermocouples are known, in which the thermal inertia index is 5-20 s. Thermocouples in conventional fittings have a thermal inertia of several minutes.

Induction transducers are used to measure the speed of linear and angular displacements. The output signal of these converters can be integrated or differentiated in time using electrical integrating or differentiating devices. After these transformations, the informative signal parameter becomes proportional to displacement or acceleration, respectively. Therefore, induction transducers are also used to measure linear and angular displacements and accelerations.

Induction transducers are most widely used in instruments for measuring angular velocity (tachometers) and in instruments for measuring vibration parameters.

Induction transducers for tachometers are small (1-100 W) DC or AC generators, usually with independent excitation from a permanent magnet, the rotor of which is mechanically connected to the shaft under test. When using a direct current generator, the angular velocity is judged by the EMF of the generator, and in the case of using an alternating current generator, the angular velocity can be determined from the value of the EMF or its frequency.

On fig. 11-21 shows an inductive transducer for measuring amplitude, speed, and acceleration of reciprocating motion. The converter is a cylindrical coil /, moving in the annular gap of the magnetic circuit 2. Cylindrical permanent magnet 3 creates a constant radial magnetic field in the annular gap. The coil, when moving, crosses the lines of force of the magnetic field, and an emf appears in it, proportional to the speed of movement.

Rice. 11-21. Induction transducer

The errors of induction transducers are determined mainly by the change in the magnetic field over time and with temperature changes, as well as temperature changes in the resistance of the winding.

The main advantages of induction transducers are the relative simplicity of design, reliability and high sensitivity. The disadvantage is the limited frequency range of the measured values.

Piezoelectric transducers. Such transducers are based on the use of the direct piezoelectric effect, which consists in the appearance electric charges on the surface of some crystals (quartz, tourmaline, Rochelle salt, etc.) under the influence of mechanical stresses.

A plate is cut out of a quartz crystal, the edges of which must be perpendicular to the optical axis Oz, mechanical axis OU and electrical axis Oh crystal (Fig. 11-22, a and b).

Fx along the electric axis on the faces X charges appear Q x = kF x , where k- piezoelectric coefficient (module).

When exposed to the force plate Fy along the mechanical axis on the same faces X charges arise Q y = kF y a/b, where a and b- dimensions of the plate faces.

Mechanical action on the plate along the optical axis does not cause the appearance of charges.

The device of a piezoelectric transducer for measuring variable gas pressure is shown in fig. 11-23. Pressure R through a metal membrane / transmitted to sandwiched between metal gaskets 2 quartz plates 3.

Rice. 11-22. Quartz crystal (a) and plate (b), carved from it

Ball 4 contributes to a uniform distribution of pressure over the surface of the quartz plates. The middle spacer is connected to pin 5 passing through a bushing of good insulating material. When subjected to pressure R a potential difference occurs between pin 5 and the converter housing .

In piezoelectric transducers, quartz is mainly used, in which the piezoelectric properties are combined with high mechanical strength and high insulating qualities, as well as with the independence of the piezoelectric characteristic from temperature over a wide range. Polarized ceramics of barium titanate, titanate and lead zirconate are also used.

Rice. 11-23. Piezoelectric pressure transducer

The dimensions of the plates and their number are chosen based on design considerations and the required charge value.

The charge that occurs in the piezoelectric transducer "flows" along the insulation and the input circuit measuring instrument. Therefore, devices that measure the potential difference on piezoelectric transducers must have a high input resistance (10 12 -10 15 Ohm), which is practically ensured by the use of electronic amplifiers with high input resistance.

Due to the "drain" of the charge, these converters are used to measure only rapidly changing quantities (variable forces, pressures, vibration parameters, accelerations, etc.).

Piezoelectric transducers are used - piezoresonators, which use both direct and reverse piezoelectric effects. The latter lies in the fact that if an alternating voltage is applied to the electrodes of the transducer, then mechanical oscillations will occur in the piezo-sensitive plate, the frequency of which ( resonant frequency) depends on the thickness h plate, modulus of elasticity E and density p of its material. When such a converter is included in the resonant circuit of the generator, the frequency of the generated electrical oscillations is determined by the frequency f p . When changing values h, E or p under the influence of mechanical or thermal influences, the frequency /p will change and, accordingly, the frequency of the generated oscillations will change. This principle is used to convert pressure, force, temperature and other quantities into frequency.

Galvanic converters. The converters are based on the dependence of the electromotive force of a galvanic circuit on the chemical activity of electrolyte ions, i.e. on the concentration of ions and redox processes in the electrolyte. These converters are used to determine the reaction of a solution (acidic, neutral, alkaline), which depends on the activity of the hydrogen ions of the solution.

Distilled water has a weak but well-defined electrical conductivity, which is explained by the ionization of water. The chemical activity a is equal to the product of the equivalent concentration and the activity coefficient (tending to unity with infinite dilution of the solution).

If an acid is dissolved in water, which forms H + ions during dissociation, then the concentration of H + ions in the solution will become greater than in pure water, and the concentration of OH ~ ions will be lower due to the recombination of part of the H + ions with OH ions.

Thus, the chemical activity of the hydrogen ions of a solution is a characteristic of the reaction of the solution. The solution reaction is numerically characterized by the negative logarithm of the activity of hydrogen ions - the pH value. For distilled water, the pH value is 7 pH units.

pH range aqueous solutions at t = 22 °С is 0-14 pH units.

To measure pH, a method based on measuring the electrode (boundary) potential is used.

If a metal electrode is immersed in a solution containing its ions of the same name, then the electrode acquires a potential. The hydrogen electrode behaves similarly.

To obtain the electrode potential between hydrogen and solution, it is necessary to have a so-called hydrogen electrode. A hydrogen electrode can be created by taking advantage of the adsorption property of hydrogen on the surface of platinum, iridium, and palladium. Typically, the hydrogen electrode is a platinum black coated platinum electrode to which hydrogen gas is continuously supplied. The potential of such an electrode depends on the concentration of hydrogen ions in the solution.

In practice, it is impossible to measure the absolute value of the boundary potential. Therefore, a galvanic converter always consists of two half-cells electrically connected to each other: a working (measuring) half-cell, which is a test solution with an electrode, and a comparative (auxiliary) half-cell with a constant boundary potential, consisting of an electrode and a solution with a constant concentration. A hydrogen electrode with a normal constant concentration of hydrogen ions is used as a reference half cell. For industrial measurements, a more convenient reference calomel electrode is used.

Rice. 11-24. Galvanic Converter

On fig. 11-24 shows a transducer for measuring the concentration of hydrogen ions. A calomel electrode serves as a comparative half-element. It is a glass vessel 4, on the bottom of which a small amount of mercury is placed, and on top of it is a paste of calomel (Hg2Cb). A solution of potassium chloride (KC1) is poured on top of the paste. The potential arises at the calomel-mercury interface. For contact with mercury, a platinum electrode 5 is soldered into the bottom of the vessel. The potential of the calomel electrode depends on the concentration of mercury in the calomel, and the concentration of mercury ions, in turn, depends on the concentration of chloride ions in the potassium chloride solution.

A hydrogen electrode is immersed in the test solution. Both half-cells are connected by an electrolytic key, which is a tube 2, usually filled with a saturated solution of KC1 and closed with semi-permeable plugs 3. The EMF of such a transducer is a function of pH.

In industrial-type devices, instead of working hydrogen electrodes, more convenient antimony or quinhydrone electrodes are used. The so-called glass electrodes are also widely used.

To measure the EMF of galvanic converters, compensation devices are mainly used. For glass electrodes, the measuring circuit must have a high input resistance, since the internal resistance of glass electrodes reaches 100-200 MΩ. When measuring pH with galvanic transducers, corrections must be made for temperature effects.

1. What is the device, working principle and application:

a) photoelectric converters;

Photovoltaic converters are those in which the output signal changes depending on the light flux incident on the converter. Photovoltaic converters or, as we will call them in the following, photocells are divided into three types:

1) photocells with external photoelectric effect

They are vacuum or gas-filled spherical glass containers, on the inner surface of which a layer of photosensitive material is applied, forming a cathode. The anode is made in the form of a ring or grid of nickel wire. In the darkened state, a dark current passes through the photocell as a result of thermionic emission and leakage between the electrodes. When illuminated, the photocathode imitates electrons under the influence of photons of light. If a voltage is applied between the anode and cathode, then these electrons form an electric current. When the illumination of a photocell included in an electrical circuit changes, the photocurrent in this circuit changes accordingly.

2) photocells with internal photoelectric effect

They are a homogeneous semiconductor plate with contacts, for example, made of cadmium selenide, which changes its resistance under the action of a light flux. The internal photoelectric effect consists in the appearance of free electrons knocked out by light quanta from the electronic orbits of atoms remaining free inside the substance. The appearance of free electrons in a material, such as a semiconductor, is equivalent to a decrease in electrical resistance. Photoresistors have high sensitivity and a linear current-voltage characteristic (CVC), i.e. their resistance does not depend on the applied voltage.

3) photovoltaic converters.

These converters are active light-sensitive semiconductors that, when light is absorbed, due to photoelectric effects in the barrier layer, create free electrons and EMF.

A photodiode (PD) can operate in two modes - photodiode and generator (valve). Phototransistor - a semiconductor receiver of radiant energy with two or more p - "-junctions, in which a photodiode and a photocurrent amplifier are combined.

Phototransistors, like photodiodes, are used to convert light signals into electrical signals.

b) capacitive transducers;

A capacitive transducer is a capacitor whose capacitance changes under the action of a measured non-electric quantity. As a capacitive converter, a flat capacitor is widely used, the capacitance of which can be expressed by the formula C \u003d e0eS / 5, where e0 is the dielectric constant of air (e0 \u003d 8.85 10 "12F / m; e is the relative permittivity of the medium between the capacitor plates; S- facing area; 5-distance between facings)

Since the measured non-electrical quantity can be functionally related to any of these parameters, the design of capacitive transducers can be very different depending on the application. To measure the levels of liquid and granular bodies, cylindrical or flat capacitors are used; for measuring small displacements, rapidly changing forces and pressures - differential capacitive transducers with a variable gap between the plates. Consider the principle of using capacitive transducers to measure various non-electrical quantities.

c) thermal converters;

A thermal converter is a current-carrying conductor or semiconductor with a high temperature coefficient, which is in heat exchange with the environment. There are several ways of heat exchange: convection; thermal conductivity of the medium; thermal conductivity of the conductor itself; radiation.

The intensity of heat exchange between the conductor and the environment depends on the following factors: the speed of the gas or liquid medium; physical properties of the medium (density, thermal conductivity, viscosity); environment temperature; geometric dimensions of the conductor. This dependence of the temperature of the conductor, and consequently, its resistance on the listed factors can be

be used to measure various non-electric quantities characterizing a gas or liquid medium: temperature, velocity, concentration, density (vacuum).

d) ionization converters;

Ionization transducers are such transducers in which the measured non-electric quantity is functionally related to the current of the electronic and ionic conductivity of the gaseous medium. The flow of electrons and ions is obtained in ionization converters either by ionization of the gas medium under the influence of one or another ionizing agent, or by thermionic emission, or by bombarding the molecules of the gas medium with electrons, etc.

Mandatory elements of any ionization transducer are a source and a receiver of radiation.

e) rheostat converters;

A rheostat transducer is a rheostat, the engine of which moves under the action of a measured non-electric quantity. A wire is wound with a uniform pitch on a frame made of insulating material. The insulation of the wire at the upper border of the frame is stripped, and the brush slides over the metal. The additional brush slides over the slip ring. Both brushes are isolated from the drive roller. Rheostatic transducers are made both with a wire wound on a frame and a rheochord type. Nichrome, manganin, constantan, etc. are used as wire material. In critical cases, when the requirements for wear resistance of contact surfaces are very high or when contact pressures are very low, platinum alloys with iridium, palladium, etc. are used. The rheostat wire must be covered with either enamel or a layer of oxides to isolate adjacent turns from each other. Engines are made of two or three wires (platinum with iridium) with a contact pressure of 0.003 ... 0.005 N or lamellar (silver, phosphor bronze) with a force of 0.05 ... 0.1 N. The contact surface of the wound wire is polished; the width of the contact surface is equal to two or three wire diameters. The frame of the rheostatic transducer is made of textolite, plastic or aluminum coated with insulating varnish or oxide film. Frame shapes are varied. The reactance of rheostat transducers is very small and can usually be neglected at frequencies in the audio range.

Rheostatic transducers can be used to measure vibration accelerations and vibration displacements with a limited frequency range.

f) strain gauge transducers;

A strain gauge transducer (strain gauge) is a conductor that changes its resistance during tensile or compression deformation. The length of the conductor / and the cross-sectional area S change with its deformation. These deformations of the crystal lattice lead to a change in the resistivity of the conductor p and, consequently, to a change in the total resistance

Application: to measure deformations and mechanical stresses, as well as other static and dynamic mechanical quantities that are proportional to the deformation of an auxiliary elastic element (spring), such as path, acceleration, force, bending or torque, gas or liquid pressure, etc. These measured quantities can be used to determine derived quantities, such as mass (weight), tank filling level, etc. Paper-based wire strain gauges, as well as foil and film strain gauges, are used to measure relative strains from 0.005 ... 0.02 to 1.5 ... 2%. Free wire strain gauges can be used to measure strains up to 6...10%. Strain gauges are practically inertialess and are used in the frequency range of 0...100 kHz.

g) inductive transducers;

Inductive measuring transducers are designed to convert position (displacement) into electrical signal. They are the most compact, noise-resistant, reliable and economical measuring transducers for solving the problems of automating the measurement of linear dimensions in mechanical engineering and instrumentation.

The inductive transducer consists of a housing in which a spindle is placed on the rolling guides, at the front end of which there is a measuring tip, and at the rear - an armature. The guide is protected from external influences by a rubber cuff. The armature connected to the spindle is located inside the coil fixed in the body. In turn, the coil windings are electrically connected to the cable fixed in the housing and protected from kinks by a conical spring. At the free end of the cable there is a connector used to connect the converter to the secondary device. The body and spindle are made of hardened stainless steel. The adapter connecting the armature to the spindle is made of titanium alloy. The spring that creates the measuring force is centered, which eliminates friction when the spindle moves. This design of the transducer provides a reduction in random error and variation in readings to a level of less than 0.1 µm.

Inductive transducers are widely used mainly for measuring linear and angular displacements.

h) magnetoelastic transducers;

Magnetoelastic transducers are a type of electromagnetic transducers. They are based on the phenomenon of changes in the magnetic permeability μ of ferromagnetic bodies depending on the mechanical stresses σ arising in them, associated with the action of mechanical forces P on the ferromagnetic bodies (tensile, compressive, bending, twisting). A change in the magnetic permeability of the ferromagnetic core causes a change in the magnetic resistance of the core RM. A change in RM leads to a change in the inductance of the coil Llocated on the core. Thus, in the magnetoelastic transducer we have the following chain of transformations:

P -> σ -> μ -> Rm -> L.

Magnetoelastic transducers can have two windings ( transformer type). Under the action of a force due to a change in magnetic permeability, the mutual inductance M between the windings and the induced EMF of the secondary winding E change. The conversion circuit in this case has the form

P -> σ -> μ -> Rm -> M -> E.

The effect of changing the magnetic properties of ferromagnetic materials under the influence of mechanical deformations is called the magnetoelastic effect.

Magnetoelastic transducers are used:

For measuring high pressures (greater than 10 N/mm2, or 100 kg/cm2), since they directly perceive pressure and do not need additional transducers;

To measure strength. In this case, the measurement limit of the device is determined by the area of the magnetoelastic transducer. These transducers deform very little under the action of force. Yes, at l= 50 mm, △ l < 10 мкм они имеют высокую жесткость и собственную частоту до 20... 50 кГц. Допустимые напряжения в материале магнитоупругого преобразователя не должны превышать 40 Н/мм2 .

i) electrolytic resistance converters;

Electrolytic converters are a type of electrochemical converters. In the general case, an electrochemical converter is an electrolytic cell filled with a solution with electrodes placed in it, which serve to turn the converter into a measuring circuit. As an element of an electrical circuit, an electrolytic cell can be characterized by the EMF it develops, the voltage drop from the passing current, resistance, capacitance and inductance. By highlighting the relationship between these electrical parameters and the measured non-electrical quantity, as well as suppressing the action of other factors, it is possible to create transducers for measuring the composition and concentration of liquid and gaseous media, pressures, displacements, speeds, accelerations, and other quantities. The electrical parameters of the cell depend on the composition of the solution and electrodes, chemical transformations in the cell, temperature, the rate of movement of the solution, etc. The relationship between the electrical parameters of electrochemical converters and non-electrical quantities is determined by the laws of electrochemistry.

The principle of operation of electrolytic converters is based on the dependence of the resistance of an electrolytic cell on the composition and concentration of the electrolyte, as well as on the geometric dimensions of the cell. Liquid column resistance of the electrolytic converter:

R = ρh/S = k/૪

where ૪= 1/ρ is the specific conductivity of the electrolyte; k - converter constant, depending on the ratio of its geometric dimensions, usually determined experimentally.

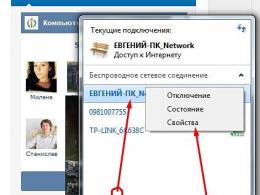

General remarks. Parametric transducers, as noted in Section 1, control the parameters of the energy flow coming from an external source and can operate in one of two modes. In the first of these, the converter is a DC current or voltage regulator.

Measuring information is carried by the law of change in the level of an electrical quantity. Although such a converter must fundamentally be a non-linear system, under certain conditions its output signal can be considered linearly related to the input, and even there is an analogy with generator MEPs. For example, in the simplest case, a converter having an electrical impedance is connected in series with the load and is powered from a source with and internal resistance An external influence changes the impedance of the converter by as a result of which the current in the circuit changes by the value From here we have

The nonlinearity of the transformation introduces the product Ho at

If the impedance is linearly related to the input value of the MEP (usually this is a displacement, i.e., then we can write

![]()

If an electric force acts in the converter and where do not depend on then the force balance equation takes the form

The last two equations are similar to the system of equations (1) and (2), and If then such a converter is equivalent to a generator MEP, and it can be called quasi-invertible. The general remarks of section 2 remain valid for it. direct current, can be quasi-reversible only under the condition that the energy of the power source is spent mainly on creating an electric or magnetic field in the converter. If the field is small, then there are no ponderomotive snals. Almost the same result is obtained when powered by alternating current due to the difference in the spectral composition of the input and output values (the converter, being a modulator, transfers the spectrum, see Chapter 10).

The output signal of the converter can be current (at or voltage at the load (in the opposite case).

In addition to the current regulator mode, the parametric MEC can operate in the exciter mode, being part of the frequency-setting circuit of the generator with self-excitation. The measured value modulates the frequency of the generated voltage. The change in frequency can be directly used as an output signal or converted to another form (discrete or analog). In this mode, the converter is always irreversible.

Rice. 10. Capacitive transducer: o - with a variable gap (area); 6 - with variable permeability; c - differential

The output signal of a parametric MEP powered by alternating current must be subjected to detection (demodulation), usually carried out in amplifying-converting equipment. Since this signal acts against the background of another that does not carry useful information, but is stronger due to the fact that its selection is carried out by differential or bridge circuits.

Capacitive converter. The principle of operation of this converter is based on the dependence of the capacitance between the conductors on their relative position, size and properties of the medium between them. In the simplest case of a flat capacitor, its capacitance is

where is the area of the electrodes; 6 - gap between them; effective (i.e., taking into account the inhomogeneity of properties) permittivity of the interelectrode space. Possible schematic diagrams of the capacitive converter are shown in fig. 10. There are two types of capacitance dependences on the displacement x of one of the electrodes:

The first of them corresponds to a change in area or effective permeability, the second - to a change in the gap.

For the first type

and for the second

![]()

Thus, equation (30) can be written in the following form:

where or for species 1 and 2, respectively.

The expression for essentially depends on the electrical mode of the converter. Due to the complexity of the analysis, in general terms, we restrict ourselves to two extreme cases when powered from a constant voltage source.

1 Capacitance changes occur so slowly that the power supply has time to charge the capacitance almost without delay, maintaining the same voltage on it, equal if no other capacitances are connected in series with the converter. Then (32) takes the following form:

![]()

On the other hand, and since equal to or -

Since the charge on the capacitance

where is the variable part of the charge, then for type 2 we can write:

2. Changes in capacitance occur so quickly that the charge on it does not have time to change significantly and remains equal to the initial value. Therefore, the voltage across the capacitance changes according to the law. If the charge does not change, then the current passing through the capacitance is zero, and the power source is needed essentially only for the initial charge of the capacitance (neglecting the leakage current). However, there is a small current through the load supported by the work of an external force For the dependence of the first type of capacitance on displacement (see page 197)

i.e., in addition to the constant force, there is additional electrical elasticity. For the second kind of dependency

![]()

Equation (32) is written in the following form

the second term is explained by the fact that at the beginning (at ) the impedance is capacitive? and not the load, determines the nature of the initial current.

The converter equations in all modes and their solutions are summarized in Table. 2.

2. Equations of a capacitive transducer

(see scan)

From the table. 2 expressions, it can be seen that in all cases the output current directly or indirectly depends on. When operating in a constant voltage mode and with an elastic character, the converter is a differentiator. In constant charge mode, the output signal depends on the type of load, in particular, if the load is active, then the current is proportional to the force. However, in any case, it is impossible to measure constant forces or displacements. 2 shows that in one of the modes the converter is quasi-reversible.

When the converter is powered from an alternating voltage source, current flows through it, even if the capacitance does not change, and the current can serve as a measure of capacitance for any law of its change. For the calculation, equation (32) should be used, taking into account what is a function. For example, when powered by a sinusoidal frequency voltage, the formulas in Table. 2, you can determine the amplitude of the output current if, instead of the expression in front, take its module at a frequency called the carrier, choose much more highest frequency in the spectrum Depending on the ratio, the converter can operate in two extreme modes of short circuit and idling. In the first of them, the equation takes place

![]()

and in the second

![]()

The expressions for are divided into two parts, the first one being independent of time, and the second pulsating with a frequency, they can almost always be neglected (see below), the converter is considered irreversible

The calculation shows that at right choice in any mode, the amplitude of the transducer output drive can be proportional to the applied force. For example, for idle mode and variable clearance

![]()

Therefore, it is necessary to choose so that the denominator is constant. With the elastic nature of the impedance, this corresponds to an active load: Bridge circuits are usually used for measurement.

The highest specific attraction force of the transducer electrodes is determined by the breakdown field strength and for air is . If the acting force in all modes is largely greater than the electrical interaction force, then the use of the transducer only at narrows the possible range of change in the input value. An increase leads to a rapid increase in the nonlinearity of the transformation, which can be reduced by using various linearization methods. One of them is the use of differential converters (Fig. 10, c), in which the capacitances change simultaneously in different directions. In this case, along with linearization and an increase in sensitivity, a good compensation for the influence of external conditions is achieved. Linearity increases significantly if the output is the inverse of A C, such as a change in capacitance. Its linear connection with x is observed until the transducer electrodes are closed. Direct linearization can be done by converting the output signal in an additional microprocessor-based unit, which is now quite possible even in self-powered devices.

If the capacitance is included in the driving circuit of the alternating voltage generator, then it is possible to measure not currents or voltages, but time parameters - frequency or duration. In a classical oscillator with an inductance, the period of oscillation is proportional, while in a RC oscillator it depends linearly on C. This method has great flexibility, since you can always choose the optimal type of output signal. For example, when the converter is switched on with a variable gap in the circuit of a resistive-capacitive generator, the oscillation frequency

![]()

The change in frequency is proportional to x and it is advisable to use it as an output signal. If the transducer has a variable area, then the oscillation period is linearly related to the displacement

Therefore, in both cases, it is possible to operate without the above limitation with high overload tolerance. When the converter is included in the oscillatory circuit, these properties are largely lost, but much greater stability of the generator parameters is achieved. Therefore, the latter method is widely used in highly sensitive and stable measuring systems. The inverter with frequency output is irreversible in all cases.

The sensitivity of a capacitive transducer is determined by its geometric relationships, supply voltage and structural stability. The highest sensitivity is achieved with a variable gap, but at the same time the upper limit of measurement is reduced. Therefore, the areas of application of transducers with variable area and variable gap are different. Transducers with variable permeability are rarely used in mechanical measurements, although there are crystalline substances with a large dependence of permeability on mechanical stress. Such dielectrics can be effective in force and pressure transducers.

Capacitive transducers are used to measure forces and quantities reduced to them, as well as displacements, especially small and ultra-small ones.

Inductive converter. The action of inductive MEPs is based on the use of the dependence of the inductance of a current-carrying circuit or the mutual inductance of two connected circuits on their size, shape, relative position and magnetic permeability of the environment in which they are located. In particular, the inductance of a coil with a magnetic core having a gap depends on the length of the latter (Fig. I).

Let us assume that the annular gap through which the lines of force passing outside the coil are closed is so small that it can be neglected. If denoted by the absolute magnetic permeability of the core; I - the average length of the power line in the core; the inductance of a coil without a core, then the inductance shown in Fig. 11 coils where the effective magnetic permeability is given the gap;

![]()

This formula is true for If, in addition to this, then

![]()

In this way,

where is the inductance at

Rice. 11. Inductive transducer: 1 - fixed core; 2 - coil; 3 - movable core

The energy of the magnetic field in the coil

![]()

where current at If we confine ourselves to terms of the 2nd order of smallness and take into account that then

Substituting these quantities into (30), (31) and taking into account that we obtain the converter equations

It can be seen from these equations that the converter is quasi-reversible with a coefficient (but not ) equal to

Output current

As usual, in the pre-resonant region, the transducer is a differentiator, and beyond the resonance, it is a scale one. Power supply for inductive transducer constant voltage not practiced, because, unlike capacitive, it consumes energy that is uselessly spent on its active resistance. When powered by alternating voltage, energy consumption decreases and becomes

possible measurement of constant values. The output parameters are calculated in the same way as for a capacitive transducer. The conclusions about the possibility of using time or frequency methods of measurement and linearization remain valid.

Converters have many design varieties. In addition to transducers with a variable gap length, which are characterized by the greatest sensitivity to the movement of the core, transducers with a variable gap area are known; with an open magnetic circuit (without a fixed core); with variable mutual inductance, etc. Their sensitivity is sufficient to measure displacements up to

Inductive transducers are used to measure displacements and the forces and pressures converted into them.

Magnetoelastic transducer differs from inductive by the mechanism of change in inductance. It is carried out by direct action of force on a ferromagnetic core (Fig. 12). It is known that the permeability of a ferromagnet depends on the mechanical stresses in the material. If, in the absence of voltage, the permeability is equal, then the creation of voltage a changes it to The sensitivity of a ferromagnet to stresses is characterized by a coefficient that depends on a and the field in the ferromagnet In a certain range of change, then the inductance of the coil can be taken top end, height, then

![]()

Rice. 12. Magnetoelastic transducer: 1 - core; 2 - coil

Substituting this value into (30), we obtain an equation for the output current of the converter. The magnetoelastic transducer is always fed with alternating voltage, which makes it practically irreversible. The output signal is found by a formula similar to (35). Since the coefficient values can reach several hundreds, the converter is sensitive to small voltages. However, noise in a ferromagnet and hysteresis phenomena limit the minimum measurable voltages to a value of the order

A natural field of application for a magnetoelastic transducer is the measurement of forces and pressures. However, it is used less frequently than inductive, mainly for measuring slowly changing quantities of the same sign.

Resistive converters. The action of resistive MEPs is based on the use of the dependence of the quantities included in the formula for electrical resistance - the length of the conductor of its cross section and the specific electrical conductivity of the material y - on mechanical influences. In the simplest case, a resistive MEP is a straight or spiral-wound wire with a variable active length determined by the position of the sliding contact (Fig. 13). Such a converter is called a rheostat. The depicted helical-wound transducer is not analog, but discrete with a step equal to the turn-to-turn distance. When the contact is moved by x, the relative change in resistance is where I is the length of the winding. Thus, it can vary from to unity, but usually the initial position of the contact is chosen in the middle of the winding. Another example is a strain gauge - a current-conducting element that is subjected to deformation, more often uniaxial (Fig. 14). In this case, all the quantities on which the resistance depends are changed.

To assess the properties of the material of the strain gauge, a strain sensitivity coefficient is introduced equal to Calculation of the change in wire dimensions during deformation

gives for the value where Poisson's ratio, equal to But since, in addition to this, the density of the material changes, and hence the concentration of charge carriers, and the crystal lattice is deformed, it turns out to be much larger for metals). In semiconductors, where there are two types of charge carriers and mechanical stresses change the structure of energy bands and the mobility of carriers, the strain sensitivity coefficient is an order of magnitude higher, but depends on the type of conductivity, its value and the orientation of the resistor axis relative to the crystallographic axes of the material.

Rice. 13. Rheostatic converter

Rice. 14. Strain gauge transducer

In resistive converters, the influence of the electrical side on the mechanical side can be completely neglected and both can be considered as independent. The mechanical impedance of the strain gauge is relatively small and elastic in nature; in a rheostat transducer, the sliding contact is a non-linear element (such as friction without lubrication). Sensitivity resistive converters both types, for example, by current, is determined by the formulas

where is the coefficient of transformation of the object deformation into strain gauge strain Transfer of strain is carried out either along the entire length of the strain gauge or at individual points. The designs of strain-resistive MEAs are diverse. They are made of various shapes from wire, foil, sprayed film or a piece of single crystal.

The sensitivity of strain-resistive MEAs makes it possible to measure dynamic deformations up to

Rheostatic transducers are used to measure relatively large relative displacements, and tensoresistive transducers are used to measure deformations and the quantities converted into them: forces, pressures, moments.

Converters with variable characteristic. A special kind of parametric MEC are converters with a non-linear current-voltage characteristic that changes under mechanical action on the converter. A typical example is a mechatronic converter - an electrovacuum device with a movable electrode. On fig. 15 schematically shows a diode mechatron with a movable anode. When the anode moves relative to the cathode, which occurs under the influence of a force on the elastic membrane, the diode - the dependence of the anode current on the voltage between the electrodes - changes. This can be seen from the formula for the anode current

![]()

where B is a coefficient depending on the material and temperature of the cathode and the area of the electrodes; anode voltage. The change is shown in fig. 16, in the right quadrant of which a family of characteristics is shown at different interelectrode distances. The representation of dependencies in the form of graphs is often the only possible one if there are no analytical expressions with sufficient accuracy. Since a load resistor is included in the diode circuit, equality is fulfilled as a result of which the current changes in accordance with the dynamic characteristic, the construction of which is shown in the left quadrant of Fig. 16. Despite the pronounced nonlinearity of the initial I–V characteristics, the dynamic characteristic is close to a straight line.

Rice. 15. Diode mechatronic converter: 1 - membrane, 2 - movable iodine

Rice. 16. Scheme for constructing the dynamic characteristics of the converter

Counting the anode displacement x from the initial distance 60 and denoting, therefore, the converter equations can be written:

Thus, both equations are independent. Converter output current

The mechanical impedance of the mechanotron is significant. In the pre-resonance region, which is usually a working region for this type of MEP, the converter will be scaled.

The diode mechanotron is the simplest among the converters with movable electrodes. Designs with two anodes and a differential switching circuit have been developed, made according to both diode and triode circuits, with a sensitivity of up to several hundred microamperes per micrometer. Due to their high rigidity, mechanotrons are more suitable for measuring forces and pressures.

Along with vacuum, solid-state converters are known - semiconductor diodes and triodes (transistors), in which is a function of the mechanical stress applied to the active region of the crystal: -transition, channel. Almost all known types of semiconductor devices can be used for this purpose. The effect here is achieved due to the fact that when the size of the active region changes, the concentration and mobility of charge carriers change, and in field effect transistor with an insulated gate, piezoelectric polarization also occurs in the insulating layer. Semiconductor MEAs of this type have a much lower mechanical impedance than a mechanotron and can measure small forces because their sensitivity is high; but

stability is not good enough. So far they have not become widespread.

resonator converters. Converters of this type are generators with electromechanical feedback through a frequency-selective element, the parameters of which depend on the impact produced on it (Fig. 17). A generator with a piezoelectric resonator in the feedback circuit is excited at a frequency equal to where is the propagation speed of the used sound waves; integer; I is the length of the wave path in the resonator. If a force acts on the resonator, its dimensions and mechanical properties, and with them the generation frequency, change in the first approximation in proportion to the force. Thus, the converter is a force-controlled oscillator with frequency modulation and is close to capacitive or inductive MEAs with frequency output, however, the latter uses not mechanical, but electrical resonance. But

where is the mass of the resonator; thickness; shear modulus in direction

Stability is determined by the stability of the combination of geometric and elastic parameters in brackets. Importance at the same time, the elimination of leakages of energy generated in the resonator is achieved, which is achieved by a rational choice of the type of excited waves, the design of the resonator and connecting elements.