Is it possible to make a phase inverter with your own hands. A simple method for setting up a phase inverter

Well, did you find the clue I hinted at in the last issue? There was about the "bass of the people" ...

In the service of the people

Okay, if you can't find it, I'll help you now. In the spring of 2006, together with you (I could not have done it alone) we came to a very favorable conclusion for ourselves: with the right choice of speaker and the correct calculation of the volume, a closed box can provide an absolutely, unshakably even frequency response in the car. Flat and extending into the region low frequencies as far as it is unthinkable to achieve in home audio, for any money. All you have to do is make sure that the frequency response of the subwoofer in open space begins to fall off at about (or exactly) the same place where the rise on the magic curve of the cabin transfer function begins. By moving this frequency up or down on the frequency axis, we may get some boost in the frequency response or, conversely, suffer some roll-off in relation to the mid frequencies, but one thing is certain: the sound pressure level created in the car interior by a subwoofer in a closed box below 50 - 60 Hz, will not start to fall to the lowest, infra audio frequencies, and even there it will happen not because of him, but because of the non-rigidity and leakage of the body. It was in the spring, and it can be considered good news.

In winter, or rather, in the last issue, we came to the same inexorable conclusion: a bass-reflex subwoofer cannot provide such grace in the entire low-frequency band under any realistically possible circumstances. The phase inverter was invented the devil knows when on purpose to expand the reproducible frequency band down, but in our car, this is not relevant due to the same transfer function. This seems to be bad news.

However, right there on a real example, we were convinced that the phase inverter will not expand the frequency band in the car, but it is able to significantly increase the sound pressure level at the same power supplied to the subwoofer. Again good news. Total: two good ones for one bad one, the score is in our favor. But what about the inherent uneven frequency response of the phase inverter? That's about it and there was a hint that you did not find.

In order not to search: here are the results of summarizing dozens of actually built and successfully working audio systems. The top graph is what the champions want, the bottom graph is what just a car music lover prefers. To avoid misunderstandings, we emphasize that in all cases we are talking about serious, sometimes very expensive systems.

Who is far from the people?

Then, in the fine spring of 2006, we went through the data of the “Systems” heading to find out: what kind of bass frequency response do people want to have in their car, having spent money on installation by the hands of professionals. And we found out: there are two rather dissimilar types of bass. One can be observed (or rather, heard) in the cars that received the highest marks in the competitions of the highest level. That's right: the most and the most. In such machines, the bass frequency response is very similar to the frequency response of expensive (or very expensive) home acoustics. Generalized: smooth, with minimal deviations from the horizontal "table" to the very bottom. If we take statistics on ordinary, for everyday use, cars, the curve will be significantly different there: with a fairly clearly traced rise in bass, the maximum of which falls at 40 Hz.

Why are the champions farther from the people than we expected? No, they are one of ours, they just listen to the car on the spot at competitions and, except for special cases, with the engine turned off. This is, in essence, a reproduction of domestic conditions in the cabin, hence the already noted similarity. But as soon as you start the engine and go somewhere (and, they say, the car is designed for this), the requirements for bass change dramatically, the level of low-frequency noise in the cabin of even an expensive car is unexpectedly high, but is perceived by the ear in a completely different way than noises at mid frequencies . It seems that the car is quiet, but for some reason the bass sounds of the musical accompaniment of the trip seem to subside - so our hearing adapts to the constantly acting low-frequency noise. The basses need to be raised, and in this case it is not so scary if they are not raised all at once, but only up to a certain frequency, in real phonograms the content of information below 30 Hz is extremely small.

Hence the form of the bass frequency response so beloved by the people. Hence - the extreme usefulness for car acoustics of a wonderful invention made in the first third of the last century.

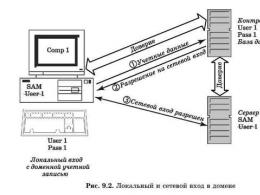

Simplified to straight forward graphics of what is happening in the cabin of the car when a subwoofer is placed there. You have already seen the top one: this is the result of an ideally audiophile setup of a subwoofer such as 3Ya. Its frequency response "at large" begins to subside precisely there and precisely with such a slope with which the transfer function of the cabin raises it. The result is an unshakable straight line and a prize cup.

See what has come

Let's repeat the illustration for one of the previous issues: the title of the series not only allows it, but also requires it. Here's the blueprint behind the Recipe for Champions. Extremely simplified, but we will stipulate all simplifications. If we agree that at the lower cutoff frequency of the frequency response of the subwoofer in a closed box, it starts to roll down sharply, with a break, and at the same frequency the transfer function turns up, then the resulting characteristic will be horizontal in a champion way. You are right, nature does not tolerate breaks, in reality the curves will bend smoothly, one down, the other up, but under certain conditions (which we discussed), the result will be the same: a flat frequency response to inaudible boundaries. Now, with the same conventions, we will draw what will happen if we build a phase inverter instead of a closed box. For greater clarity, let's first build it badly and incorrectly. This means: having remembered from the materials about “prime numbers” promising the heavenly characteristics of the SL (No. 4/2006), that the resonant frequency of the speaker in this type of design should be chosen close to the inflection frequency of the transfer function curve, we will tune the newly constructed FI to this frequency. This in practice means setting hertz commercials at 60 - 70. What will happen? But nothing good, the frequency response of the phase inverter, as already mentioned, falls below the tuning frequency twice as fast as that of a closed box, 24 dB / oct. instead of 12. The transfer function of the cabin knows nothing about this and still provides a rise in the frequency response at its inherent pace: 12 dB / oct. The result will be a "budget deficit", below the tuning frequency the resulting frequency response will go down with a slope of 12 dB / oct. Why did you have to twirl a hole in the box to get this? And it’s true, there’s no need, but we deliberately started with a bad phase inverter so that a good one would come out better.

The second graph is an example of an inappropriate transfer of the same approach to a phase inverter. Its own frequency response falls below the tuning frequency with a slope already of 24 dB / oct., the transfer function only compensates for the steepness of the decline by half, but it will start from the same unacceptably high frequency.

Let's throw out what was done earlier (thank God, mentally) and build another FI, in which the tuning frequency is significantly lower than the inflection frequency of the transfer function. Now the following happens: starting from a certain frequency, the transfer function of the cabin begins to raise the sound pressure inside, because the frequency response of the subwoofer in free space is still horizontal. When the frequency (we go from top to bottom, of course) reaches the tuning frequency, the frequency response of the subwoofer itself will go down with a slope of 24 dB / oct., 12 dB / oct. the transfer function will “correct” it, the result is a drop in recoil below the tuning frequency, like a closed box in a room.

And now look what happens between these two frequencies: until the frequency response began to drop, the phase inverter managed to gain a fair amount of sound pressure. What in our simplified scheme looks like a kind of house, is actually realized in the form of smooth curves, in the general case, similar to the shape of the frequency response of the “folk bass”. It remains the smallest thing - to put it into practice, where there are no straight lines and broken lines ...

Idealization of real PHI tuning: its finest hour falls on the range between the inflection point of the transfer function curve and the tuning frequency. The more widely spaced these two frequencies, the more space for the bass "house".

The basic principle that follows not from science at all, but from the most mundane practice, you can already deduce yourself. If the majority of the population makes (or accepts made for them) the frequency response of a subwoofer in the form of a hump with a center frequency of about 40 Hz, then why should we go against the people? Based on the above diagram, the very first, even zero approximation of the recipe for the optimal automobile (only automobile) phase inverter will be setting it to a frequency of 40 plus or minus 5 Hz. We cannot influence the transfer function in any way, it will determine where the rise in the frequency response begins. And its decline, and consequently, the maximum will fall according to our model on the frequency of the FI tuning. And that's it? Again "prime numbers"? Unfortunately no. Absolutely simple numbers for a phase inverter have not been invented. But something can still be simplified.

Freedom in degree

Indeed, there was a box, now there is a box with a tunnel, why can't we get by with simple recipes in this case as well? The point is the number of variables that determine the characteristics of the phase inverter as an oscillatory system. If in the case of a closed box we were dealing with a system with one degree of freedom, then FI has two of these degrees. Numerically, the difference is small, but in order to imagine how much more complicated the habits of the system become, we will use this illustration, you either have to imagine objects seen more than once in a certain combination, or, if there is no other occupation, take and actually build a simple experimental setup. Its first part is a banal pendulum, but at least a load on a rope. All he can do is swing back and forth, his movements are predictable to the point of uninteresting. The pendulum has one degree of freedom, its state at any moment of time is exhaustively determined by the angle of deviation from the equilibrium position. Now replace the rope with a rubber band. There are two degrees of freedom, that is, coordinates independent of each other that determine the state of such a system, so to speak: the swing angle and the degree of stretching of the rubber band. Now deflect such a pendulum to the side, while stretching the elastic band. If you really didn’t see what would start after that, take the time and haberdashery and conduct an experiment: instead of banal rocking, the load will make hard-to-describe and hard-to-predict somersaults in the air.

Approximately to the same extent, the behavior of FI differs from the predicted GL. The speaker still has three parameters, one of which, the equivalent volume, is now less important, because it determines the scale factor, and not the oscillation process, and the other two, the resonant frequency and quality factor, are still important. But acoustic design parameters have doubled: the volume of the box and the frequency of tuning the tunnel. In what ratio should these four quantities be so that we are not disappointed with the results? Serious research on the operation of a phase inverter has generated more than one dissertation and many classic scientific articles, but our task is different, so we will try to give practical guidelines without going into details why they are exactly that.

After all, look: you still have to calculate PHI with the help of a computer program, and with a 99% probability it will be BassBox or (which is the same) JBL Speaker Shop, these once commercial products now they have spread around the world in such numbers that only a very lazy person can not find another copy for himself. But a stove from which to dance, even with proven software, is still needed.

General rule: the more spacious the FI cabinet, the higher (but the sharper) the acoustic amplification hump will be

In sufficiently spacious cases, which, if they were closed, would lead to low values of the total quality factor of the speaker in the design, the peak of the return falls on the tuning frequency

In cramped cases, including those that are optimal in the role of a chirp for a given speaker, the frequency response has a maximum higher than the tuning frequency, with a completely low volume, the characteristic takes on a double-humped shape, and the benefit from using the FI fades to nothing

Unsportsmanlike orienteering

So, the first landmark, already relatively understandable from a comparison of the practical, "target" form of frequency response obtained by generalizing practice, and a simplified picture illustrating what is happening in the cabin. If we want a rise in the frequency response with a maximum around 40 Hz, at this frequency the subwoofer's frequency response should begin to decline in free space (in a room or on the street - it doesn't matter, it's important that it's not in the cabin). This frequency is, to a first approximation, the tuning frequency of the tunnel. The same practice demonstrates with all obviousness: in all successful audio systems that use a bass-reflex subwoofer, the tuning frequency falls in the range of 30 - 40 Hz. In the same corridor, there are usually the tuning frequencies of phase inverters recommended by manufacturers for their subwoofers. Except in special cases sports application, we are not talking about that now. Looking at a conditionally simplified diagram, you can figure out that, other things being equal, the lower the frequency of the FI tuning, the higher the frequency response in the cabin will have time to climb before it starts to fall with the same slope. You can see this from the actual materials: take a look at one of our cabinet subwoofer tests and compare the tuning frequency of the tunnel (for those who have it) with the position of the maximum sound pressure recorded during measurements in the cabin.

However, the position of the hump in frequency is one thing, and its height is another. How to achieve the desired smooth rise in bass in a reasonably wide frequency band, so that the frequency response does not stand like a first-year blanket? There are guidelines for this as well. General rule: other things being equal (we make this reservation all the time, and it is clear why - due to the increased number of variables), the rise in the frequency response near the tuning frequency will be the higher and sharper, the larger the volume of the PHI box. How to choose the first approximation of the volume? There is a simple (finally) recipe, behind which, however, there are far from simple conclusions of the classics of modern electroacoustics. Take such a volume that, if it were a closed box, would give a value for the total quality factor of the head in the design, equal to about 0.55 - 0.6. It is precisely because of this that the optimal amount of FI in the overwhelming majority of cases is greater than the optimal EP for the same speaker, because the EP is calculated based on the resulting quality factor of 0.7, or even higher.

With such a volume (and here, of course, not so much the absolute value of the volume plays a role, but rather its ratio to the equivalent volume of the speaker Vas), you can count on the correct operation of the resulting acoustic design, firstly, and on the fact that the maximum output will be near the tuning frequency - Secondly. You need a higher, albeit more "house", rise in frequency response - increase the volume. You need a rise lower, but smoother and in a wider frequency band - reduce the volume, just be prepared for two things in advance: along with smoothing the maximum, it will tend to move higher in frequency with a decrease in volume, and will no longer strictly correspond to the port tuning frequency, and when the volume reaches the optimal value for this closed box speaker, with a very high probability the frequency response will acquire a rather awkward saddle shape, while the acoustic amplification, the very hump that we are trying to build, will in most cases come to naught.

However, before starting experiments with the selection (and it doesn’t work in another way, no one has yet been able to calculate the FI with one click) volume and settings, you need to decide on the speaker. Here it will be necessary for us, alas, to destroy one delusion.

Back in the EBP arena

We have already talked about this value, the abbreviated name of which stands for Energy Bandwidth Product. This value, numerically equal to the ratio of the resonance frequency of the speaker to its full quality factor, we have already used when choosing a speaker for the soundtrack. But long before us, for many years now it has been called upon to use it to sort speakers into those intended for closed boxes and asking for a phase inverter. It is generally accepted that if this value is less than 50, the speaker is intended only for the WA. If more than 100 - only for PHI, between these two values a certain twilight zone extends, where it can be either way or that.

Experience shows the relative low utility of this indicator for selecting the design of car subwoofers, although the idea is sound in principle. Small EBP means: the resonant frequency is low, the quality factor is relatively high, which indicates a heavy moving system, and according to the canon, such a speaker really goes to the SL. A large EBP value indicates a slight “movement”, such heads really make excellent phase inverters, but ... at home.

We have, firstly, a huge, overwhelming number of subwoofer heads have an EBP parameter value in the range of 50 - 80, which means uncertainty for a pessimist, and freedom of choice for an optimist. Secondly, and this is already from practice, good FI is not obtained in the car on the speakers with canonically good readings for this. A phase inverter on a speaker with a low quality factor (and it turns out that if EBP exceeds a hundred) in free space will show a flat frequency response with a peculiar, perhaps, behavior near the lower cutoff frequency, in a car this peculiarity will add up with the transfer function and generate, almost without exception, rather ugly feature.

Our testers also contributed to the relative debunking of the "energy product" by conducting a study on real samples of subwoofer heads. The result was as follows: with an EBP value of about 50 (according to the canon - in WL, and without talking) there is a chance to get a very good acoustic amplification in FI while maintaining a decent shape of the frequency response, at 90 (according to the canon it is already asking for in FI), the gain in recoil falls below 3 dB, why, one wonders, take a steam bath? So for our brother, everything turns out almost the opposite: the most effective FI come out on the basis of the most “box” heads. This is how we are set up...

I started doing column building in the early 80s. And if at first it was just a “speaker in a box”, then, naturally, the study of the influence of the parameters of the box (and the phase inverter) on the sound of the speaker began.

There are many "subwoofer builders" out there, but for the vast majority it's just a "speaker in a box" and the more the better. Yes, to some extent, for a closed box, this is correct. But for a phase inverter ...

The phase inverter requires careful tuning. What do we see in practice? As a phase inverter, people put sewer pipes of arbitrary length, make "slotted phase inverters" in the image: "Vasya did this size," while putting another speaker. The one who represents this is limited to the manufacture of a closed box (and he does it right!).

Of course, there are great simulation programs out there like JBL SpeakerShop. But they all require the introduction of a bunch of initial parameters. And even knowing them, the discrepancy with practice turns out, as a rule - huge(the speaker turned out to be slightly different, the box is slightly different in size, we don’t know what and how much filler, the phase inverter pipe is slightly different, we don’t know the acoustic resistance, etc.)

There is a simple technique for setting up a phase inverter that does not require knowledge of the exact initial data of the speakers, boxes, and does not require complex measuring instruments or mathematical calculations. Everything has already been thought out and tested in practice!

I want to talk about a simple method for setting up a phase inverter, which gives an error of no more than 5%. A technique that has existed for over 30 years. I have used it since I was a student.

What is the difference between a box with a phase inverter and a closed box?

Any speaker, like a mechanical system, has its own resonant frequency. Above this frequency, the speaker sounds “pretty smooth”, and below this frequency, the level of sound pressure it generates drops. Falls at a rate of 12 dB per octave (i.e. 4 times for a 2-fold reduction in frequency). The “lower limit of reproducible frequencies” is considered to be the frequency at which the level drops by 6 dB (i.e., 2 times).

Frequency response dynamics in open space

By installing the speaker in a box, its resonant frequency will increase somewhat, due to the fact that the elasticity of the air compressed in the box will be added to the elasticity of the diffuser suspension. Raising the resonant frequency will inevitably "pull" up and the lower limit of the reproducible frequencies. The smaller the volume of air in the box, the higher its elasticity, and, consequently, the higher the resonant frequency. Hence the desire to "make the box more-oh-oh-more."

Yellow line - frequency response of the speaker in a closed box

To some extent, it is possible to make the box "bigger" without increasing its physical dimensions. To do this, the box is filled with absorbent material. We will not go into the physics of this process, but as the amount of filler increases, the resonant frequency of the speaker in the box decreases (the “equivalent volume” of the box increases). If there is too much filler, then the resonant frequency starts to rise again.

Let's omit the influence of the box dimensions on other parameters, such as the quality factor. Let's leave it to experienced "column builders". In most practical cases, due to limited space, the volume of the box turns out to be quite close to optimal (we do not build cabinet-sized speakers). And the meaning of the article, do not download you complex formulas and calculations.

Were distracted. With a closed box, everything is clear, but what does a phase inverter give us? A phase inverter is a “pipe” (not necessarily round, it can be rectangular and a narrow slot) of a certain length, which, together with the volume of air in the box, has its own resonance. At this “second resonance”, the sound output of the speaker rises. The resonance frequency is chosen slightly lower than the resonance frequency of the speaker in the box, i.e. in the area where the speaker begins to decline in sound pressure. Consequently, where the speaker has a recession, a rise appears, which to some extent compensates for this decline, expanding the lower cutoff frequency of the reproduced frequencies.

Red line - frequency response of the speaker in a closed box with a phase inverter

It is worth noting that below the resonance frequency of the phase inverter, the sound pressure drop will be steeper than that of a closed box and will be 24 dB per octave.

Thus, the phase inverter allows you to expand the range of reproducible frequencies towards lower frequencies. So how do you choose the resonant frequency of a phase inverter?

If the resonance frequency of the phase inverter is higher than optimal, i.e. it will be close to the resonant frequency of the speaker in the box, then we will get "overcompensation" in the form of a protruding hump in the frequency response. The sound will be barrel-shaped. If the frequency is chosen too low, then the level rise will not be felt, because. at low frequencies, the speaker output drops too much (undercompensated).

Blue lines are not optimal setting phase inverter

This is a very delicate moment - either the phase inverter will give an effect, or it will not give any, or, conversely, it will ruin the sound! The phase inverter frequency must be chosen very accurately! But where can you get this accuracy in a garage-home environment?

In fact, the coefficient of proportionality between the resonance frequency of the speaker in the box and the resonance frequency of the phase inverter, in the vast majority of real designs, is 0.61 - 0.65, and if we take it equal to 0.63, then the error will be no more than 5%.

1. Vinogradova E.L. "Designing loudspeakers with smoothed frequency response", Moscow, ed. Energy, 1978

2. "More about the calculation and manufacture of a loudspeaker", w. Radio, 1984, No. 10

3. “Setting up phase inverters”, well. Radio, 1986, No. 8

Now let's transfer the theory to practice - it's closer to us.

How to measure the resonant frequency of a speaker in a box? As is known, at the resonant frequency, "the modulus of the total electrical resistance» (Impedance) of the voice coil increases. Roughly speaking, resistance is growing. If for direct current it is, for example, 4 ohms, then at the resonant frequency it will increase to 20 - 60 ohms. How to measure this?

To do this, in series with the speaker, you need to turn on a resistor with a rating an order of magnitude higher than the speaker's own resistance. A resistor with a nominal value of 100 - 1000 ohms is suitable for us. By measuring the voltage across this resistor, we can estimate the "impedance modulus" of the speaker's voice coil. At frequencies where the speaker impedance is high, the voltage across the resistor will be minimal, and vice versa. So, how do you measure?

Speaker impedance measurement

Absolute values are not important to us, we just need to find the maximum resistance (minimum voltage across the resistor), the frequencies are quite low, so you can use a regular tester (multimeter) in AC voltage measurement mode. And where to get the source of sound frequencies?

Of course, it is better to use an audio frequency generator as a source ... But let's leave it to professionals. But "no one forbids" us to create a CD with a recorded range of sound frequencies, created in any computer program, for example, CoolEdit or Adobe Audition. Even I, with measuring equipment at home, created a CD with 99 tracks, a few seconds each, with a range of frequencies from 21 to 119 Hz, in 1 Hz steps. Very comfortably! I inserted it into the radio, you jump along the tracks - you change the frequency. The frequency is equal to the track number + 20. Very simple!

The process of measuring the resonant frequency of the speaker in the box is as follows: we “plug” the phase inverter hole (a piece of plywood and plasticine), turn on the CD for playback, set an acceptable volume, and without changing it, “jump” over the tracks and find the track on which the voltage is on resistor is minimal. Everything - the frequency is known to us.

By the way, in parallel, by measuring the resonant frequency of the speaker in the box, we can choose the optimal amount of filler for the box! Gradually adding the amount of filler, we look at the change in the resonant frequency. We find the optimal amount at which the resonant frequency is minimal.

Knowing the value of the "resonant frequency of the speaker in the box with filler" it is easy to find the optimal resonant frequency of the phase inverter. Just multiply it by 0.63. For example, we got the resonant frequency of the speaker in the box at 62 Hz - therefore, the optimal resonant frequency of the phase inverter will be about 39 Hz.

Now we “open” the opening of the phase inverter, and by changing the length of the pipe (tunnel) or its cross section, we tune the phase inverter to the required frequency. How to do it?

Yes, using the same resistor, tester and CD! You just need to remember that at the resonance frequency of the phase inverter, on the contrary, the “modulus of electrical impedance” of the speaker coil drops to a minimum. Therefore, we need to look not for the minimum voltage across the resistor, but, on the contrary, the maximum - the first maximum, which is below the resonance frequency of the speaker in the box.

Naturally, the tuning frequency of the phase inverter will differ from the required one. And believe me - very strongly ... Usually, towards low frequencies (undercompensation). To increase the tuning frequency of the phase inverter, it is necessary to shorten the tunnel, or reduce its cross-sectional area. You need to do this gradually, half a centimeter ...

Something like this in the low-frequency region will look like the electrical impedance module of the speaker in a box with an optimally tuned phase inverter:

Here is the whole technique. Very simple, and at the same time, giving a fairly accurate result.

The logical finale of the phase inverter saga will be the practical aspects of its implementation. The key element here is precisely the pipe, which is also a tunnel, which, as a result of slave transliteration from English, is a port. It is she, the pipe, that will make it possible to put into practice two main parameters that determine the acoustic appearance of the conceived phase inverter: the volume of the case and the frequency of its tuning. These two values, one in liters, the second in hertz, are the result of either an independent calculation or following previously made calculations. They may come from speaker manufacturers, our tests, or expert advice based on their practice. In all three cases, it happens that ready-made tunnel dimensions are given that ensure that a known volume is tuned to the desired frequency, but, firstly, not every time, and secondly, blind copying is not always possible and always not commendable. So the following statement of the problem will be more general and much more productive: the volume and frequency are known, and we will solve the question of their physical, in material, implementation on our own. Part of the story will be organized according to the principle of questions and answers: the nomenclature of questions is known, in the editorial mail they are repeated with regularity, giving rise to statistical calculations that our test department loves so much. I will not take away their favorite toy, we have ours. So, what at first, we calculate the tunnel or buy a pipe, which this tunnel will become? In theory, you must first buy - pipes are not of any diameter, but from a certain range of values, if you take ready-made ones, and not wrap it yourself from paper on glue, like a pioneer from a young cosmonaut's circle. But you still have to start with at least a rough estimate, and the point here is that ...

Thickness Matters

If the tunnel is really a pipe (there are options, after all), what should its diameter be? The most general and crudest answer is: the more, the better. The advice is really radical and can cause a protest reaction: what if I take and make a tunnel twice the diameter of the speaker? You won’t take it and you won’t do it, no matter how hard you try, more than a hundred years ago a certain Herman Helmholtz took care of this, the resonator of whose name the phase inverter is, and later the creators of cars, who made them smaller in size than the steam locomotives that existed at that time. So, in order, why more and why something will stop this process.

During operation, near the tuning frequency, where, in fact, the phase inverter tunnel performs its functions, adding from itself to the sound waves generated by the cone's vibrations, air moves inside the tunnel. Moves oscillatingly, back and forth. The volume of moving air is exactly the same as that during each oscillation is set in motion by the diffuser, it is equal to the product of the diffuser area and its stroke. For a tunnel, this volume is the product of the cross-sectional area and the air flow inside the tunnel. The cross-sectional area is really always less than the diffuser area (if someone has not yet abandoned the threat to make the same, or even more, they will soon not go anywhere and refuse), and in order to move the same volume, the air needs to move faster, the speed in the tunnel decreases diameter increases in proportion to the decrease in its cross-sectional area. Why is it bad? Everyone at once. First of all, the fact that the Helmholtz resonator model, on which everything is based, assumes that there is no energy loss due to air friction against the tunnel walls. This, of course, is an ideal case, but the further we move away from it, the less the operation of the phase inverter will be like what we expect from it. And the friction losses in the tunnel are the higher, the greater the air speed inside. Theoretically, the formula, and the simple program based on it, does not take into account these losses and will meekly give you the estimated length of the tunnel with a diameter of at least a finger, but such a phase inverter will not work, everything will die in the whirlwinds of air trying to rapidly fly back through the narrow tunnel - forward. The text of the traffic police propaganda poster I once saw “Speed is death” certainly fits the movement of air in the tunnel, if death is attributed to the efficiency of the phase inverter.

However, much earlier than the phasic dies as a means of sound reproduction, it will become a source of sounds for which it is not intended, the vortices that occur at excessively high air speeds will create jet noises that violate the harmony of bass sounds in the most shameless and unaesthetic way.

What should be taken as the minimum value of the tunnel cross-sectional area? In different sources you will find different recommendations, not all of them have ever been tested by the authors, at least through a computational experiment, let alone others. As a rule, two values are included in such recommendations: the diameter of the diffuser and the maximum value of its stroke, that is Xmax. This is reasonable and logical, but fully applies only to the operation of the subwoofer at the limit, when it is already a little too late to talk about sound quality. Based on numerous practical observations, a much simpler rule can be adopted, it is not perfect and not entirely universal, but it works: for an 8-inch head, the tunnel must be at least 5 cm in diameter, for a 10-inch -

7 cm, for 12 and more - 10 cm. Is it possible to do more? It is even necessary, but right now something will stop us. Namely, the length of the tunnel. The fact is that...

Length matters

As said, it will be commanded by the great Hermann von Helmholtz. Here he is, at the blackboard at the University of Heidelberg, and on the blackboard is the same formula. Well, this time I wrote it, but I came up with it - he would have written it in the same way. This simple, since it was derived for the ideal case, the dependence shows what the resonance frequency of a certain cavity will be (we are more familiar with a box, although Herman von made such bubbles with tail pipes) depending on the volume V, length L and cross-sectional area of the tail. Please note: there are no speaker parameters here, and it would be strange if they were. In any case, it is useful to remember and never succumb to provocations: the phase inverter setting is completely and exhaustively determined by the size of the box and the characteristics of the tunnel connecting this box with the environment. In addition, the formula includes only the speed of sound in the atmosphere of the planet Earth, denoted by "c", and the number "pi", which does not even depend on the planet.

For practical purposes, namely, calculating the length of the tunnel from known data, the formula is easy to convert, remembering your native school, and substitute the constants as numbers. Many did it. Many have published the results of this exciting process, and the author is a little surprised how spectacularly it was possible to crap out in an operation with three or four numbers. In general, a third of the converted formulas published on paper and on the Web are incomprehensibly nonsense. The correct one is given here if we substitute the values in units shown in black.

The same formula, plus some corrections, is included in all known programs for calculating phase inverters, but right now the formula is more convenient for us, everything is in plain sight. Look: what will happen if instead of a minimalist tunnel we put another, more spacious (and therefore better)? The required length will increase in proportion to the square of the diameter (or in proportion to the area, but we are going to buy a pipe by diameter, they don’t sell it differently). We switched from a 5 cm pipe to a 7 cm pipe, for example, the length with the same setting will need twice as much. We switched to 10 cm - four times. Trouble? So far - half the trouble. The fact is that...

Caliber matters

There will be trouble now. Once again we look at the formula, this time - at the denominator, focus your eyesight. All other things being equal, the length of the tunnel will be the greater, the smaller the volume of the box. If, in order to tune a 100-liter volume to 30 Hz, having a 100-mm plumbing pipe at your disposal, you need to open and paste a piece of shit pipe 25 centimeters long into the box, then with a box volume of 50 liters it will be half a meter (which is no less, than not so bad), and with a fairly common 25 l, a tunnel of this thickness will have to be a meter long. This is a disaster, no options.

In our practical conditions, the volume of the box is primarily determined by the parameters of the speaker, and for reasons that are already well known to readers of this series, for 8-inch heads, the optimal volume rarely exceeds 20 liters, for "tens" - 30 - 40, only when it comes to comes to 12-inch caliber, we start to deal with volumes of the order of 50 - 60 liters, and then not always.

So it turns out some kind of parade of sovereignties: the tuning frequency of the FI is determined by the bass that we want to get from it, whether it is on the “eight” or on the “tag” - it doesn’t matter. And the box tuning frequency again does not depend on the speaker, the smaller the volume, the longer the tunnel. The result of the parade: as we have repeatedly noticed in tests of small-caliber subwoofers, it is physically impossible (or difficult) to implement the desirable and promising design option in FI. Even if you don’t feel sorry for the space in the trunk, you can’t make the volume of the FI box larger than the optimal one, and the optimal one often turns out to be so small that it’s unthinkable to tune it to a frequency of 30–40 Hz that is invariant to other factors. Here is an example from a recent test of 10-inch subwoofer heads (“A3” No. 11/2006): if we take a pipe diameter of 7 cm as an axiom, then in order to make a phase inverter on a Boston head, it would take a piece 50 cm long, for Rainbow - 70 cm, And for Rockford Fosgate and Lightning Audio - about a meter. Compare with the recommendations in this issue's test for 15-inch heads: none of these problems were noted. Why? Not because of the speaker, as such, but because of the original volume selected by the speaker parameters. What to do? Face adversity head on. Weapons were forged for us by generations of specialists (and not only). Do you know what's the matter here?

Form matters

You could hardly fail to notice: I really like to delve into patents, because I think that even if the road from invention to real life is not so short, a patent is a reflection of thought in the form of a vector, that is, taking into account the direction. Most of the innovations proposed (and steadily proposed) by tireless minds in relation to the phase inverter are concentrated on combating two interfering factors: the length of the tunnel, when its cross section is large, and jet noise, when its cross section, trying to reduce the length, tried to reduce. The first, simplest solution, the admissibility of which we are asked in an editorial mail five times a month: can the tunnel be placed not inside the box, but outside? Here is the answer, final, factual and real, like a paper on Professor Preobrazhensky's apartment: you can. At least partially, at least in its entirety, the tunnel was stuffed inside the box solely for aesthetic reasons, at von Helmholtz it stuck out from the outside, and nothing, he survived it. Yes, and our modernity gives examples: for example, car audio veterans cannot help but remember (many, to be honest, cannot forget) the SAS Bazooka bass pipes. After all, they began with a patent for a subwoofer, which is conveniently placed behind the seat of a truck - the favorite transport of Americans. To do this, the inventor stretched the phase inverter pipe along the outside of the case, at the same time giving it a shape spread over the surface of the cylindrical case. This is one example, there is another: some companies that produce built-in subwoofers for home theaters bring out the tube-tunnel of a bandpass subwoofer. The type of subwoofer in this case does not matter: this is the same resonator of the name you know who. Another solution is also, judging by the letters, they are looking for, but they are afraid. "Is it possible to bend the tunnel?" The answer is in the style of Philip Philipovich and is obvious. Otherwise, several companies (DLS, JL Audio, Autoleads, etc. etc.) would not produce flexible pipes specifically for this purpose at once. And in the field of patent documentation there is even an interesting hint on how this problem can be solved not without grace and material savings: at one time, the design of a model tunnel was proposed, which would be assembled from standard elements in any desired form, the illustration will tell the rest. I’ll add on my own: most of the details depicted in the patent are touchingly reminiscent of the nomenclature of the elements of local sewer networks, which is a practical recipe for introducing the American inventor’s intellectual excess.

Struggling with the inappropriate length of the tunnel, they often follow the path of building the so-called "slotted ports", their advantage is in constructive integration with the hull, which allows, with a certain imagination, to make the tunnel quite long, on the attached diagram there are several options at once, which the question is, of course, it is far from being exhausted (the top three sketches were written by the famous high-end artist Alexander Klyachin, the rest was a matter of technique).

The disadvantage of slots is the difficulty of adjusting the length, this is not plumbing PVC - he waved the saw, and it's in the bag. But there are solutions here too: not so long ago, one of the heroes of the “Own game” column, Alexander Sultanbekov from Perm (it’s not a sin to once again remind the country of the names of its heroes) demonstrated in practice how you can adjust the slotted port by changing its cross section at a constant length, he is did by laying plywood spacers inside, as shown in the photo somewhere nearby, look.

In folding the phase inverter tunnel, some bright minds went to extremes: one bright mind suggested, for example, to roll the tunnel in the form of a spiral around the cylindrical loudspeaker case, the other answered the cunning Helmholtz formula with a screw tunnel, such a concept is familiar to us here in Russia...

But in general, all these solutions (even with a screw) are frontal, here a tunnel of constant length is simply attached or folded so that it does not interfere. Known (and even sold in commercial quantities) implementation of another principle. Here's the thing here.

Cross section matters

Not the area, as such, but the nature of its change along the length of the tunnel. Until now, we, guided by the teachings of von Helmholtz in its simplest, school form, considered it indispensable that the cross section of the tunnel is constant. And there were people who violated this condition and even made money on it.

Experienced readers will remember, for example, an article by our Italian colleague, Professor Matarazzi, where he offers effective solutions for reducing the length of the tunnel by giving it a conical or doubly conical hourglass shape. In "A3" No. 10/2001, the calculations for the professor's programs are given in the form of tables, and the senior recently found and sent the programs themselves at our request. By the time this issue goes out of print, we will put them on the site in the "Appendices" section. Truth, source the absent-minded professor has lost it forever, so the programs remain in Italian, if anyone knows how to translate without having the code, we will accept the help with gratitude.

In the meantime, we note: in his research, the professor is not the first, and not the only one. Even whole tragedies occurred in this direction. Longtime readers of the magazine may remember the note in "A3" No. 2/2003 about the lawsuit over the bass reflex tunnel, not so long ago: Bose Corporation saw that another corporation, JBL, using in its columns bass reflex tunnels with a curvilinear generatrix, called Linear-A, has gravely infringed upon the intellectual property of Bose Corp. As evidence, a US patent was cited, which mentioned, among other things, that it would be nice to make a tunnel with an elliptical generatrix, then it would be both shorter and quieter in terms of jet noise. In vain JBL tried to explain to the court that Bose has an ellipse, and JBL has an exponent. The court explained that ellipses-schmellipses are the tenth thing, and a lot of speakers were sold, Bose's accounting department calculated: JBL's profit was $5,676,718 and 32 cents, which was proposed to be paid to the offended party's cashier. They brought it in as nice ones, including coppers, and in all columns the tunnels changed to others, FreeFlow, like an improved model. Here's how it goes...

Very, very many people have suggested avoiding the cylinder as a form of tunnel. Some - in the style of Matarazzi with variations, some - on a modest, local scale, limiting themselves to giving curvilinear contours to the ends of a cylindrical tunnel in order to reduce jet noise from turbulence. The most radical means of dealing with both length and noise was not only invented, but has been exclusively used for more than one year by Matthew Polk, the founder of a company named after himself. The essence of the device called PowerPort is as follows: one or two, at each end of the pipe, take over part of the tunnel’s functions, an annular gap between the wall of the box and a “mushroom” placed at a strictly calculated distance from it, however, everything is visible in the figure. Almost all Polk Audio home loudspeakers are supplied with such tunnels. And if only someone encroached, his 32 cents cried, plus something else. For myself, my loved ones, no one will forbid trying such a thing, especially since once upon a time Polk posted a spreadsheet in Excel on his corporate website, according to which you can calculate everything, I then popped it from this site (having received later, in hindsight, the blessing of the author - I'm not for the purpose of profit) and even translated the accompanying instructions into the great and mighty, it's all on our website.

A propos, and the works of Professor Matarazzi, and the revolutionary development of Matthew Polk remind us of this: the Helmholtz gymnasium formula, among other things, does not take into account a very significant effect for practice: in the vast majority of cases (almost always) one of the ends of the tunnel is adjacent to the wall subwoofer enclosure, this applies to both round pipes sawn flush with the wall, and pipes equipped with an aerodynamic tip, and to an even greater extent - slotted ports stuck to the wall. The proximity of the wall creates an end effect reminiscent of what the author of PowerPort intentionally sought - a virtual lengthening of the tunnel. Therefore, to the formula directly derived from the works of von Helmholtz, modern applied experts recommend introducing an amendment, purely empirical, but no less necessary, it is highlighted in red so that it is clear where the classic of the 19th century is, and where is the practice of the 20th.

But in general, dear friends, it's time to get down to business, it's not a century to delve into pieces of paper. The point is just this...

On the issue of thickness: pushing the same volume of air through a tighter tunnel, it will have to be accelerated to a higher speed. And "speed is death"

Helmholtz would have written his formula in exactly the same way, just at that moment there was no photographer

The final and actual formula that replaces the computer program. She is correct, checked repeatedly. The meaning of the tail highlighted in red will be explained in the text.

Can the tunnel be outside the box? Yes, the whole company built its business on this, the patent for a convenient subwoofer was replicated by groans of thousands of SAS Bazooka bass pipes. And manufacturers of built-in subwoofers for home theaters don't care at all...

Is it possible to leave the tunnel inside, but bend it as it is more convenient? Here is your answer

Exotic, desperate solutions: spiral or screw tunnel

The slot tunnel is integrated with the drawer, so it can be made longer than the usual, “plug-in” one, adjusting the length, however, is much more difficult ...

This means that it is necessary to adjust not the length, but the cross section: this is how one resident of the capital of the Perm Territory did it

Departure from the cylindrical shape of the tunnel was proposed both to reduce its length, and in the form of a local "aerodynamic treatment" to reduce jet noise.

The most effective solution in this area: Matthew Polk's PowerPort. The invention did not remain on paper, it is component almost all Polk Audio speakers

Prepared based on the materials of the magazine "Avtozvuk", February 2007.www.avtozvuk.com

Homemade acoustics

Acoustic system with slotted bass reflex

A. ZHURENKOV, Zaporozhye, Ukraine Radio, No. 8 2013

In the described design of a three-way speaker, the author preferred a slotted phase inverter, which is less prone to organ resonances than speakers with round pipes. For the loudspeakers of this speaker, a small amplifier power is enough - 2x10 ... 20 watts. Acoustic systems (loudspeakers) with a phase inverter (FI) have now become the most common in the Hi-Fi class

This is due to the increased efficiency in the region of low sound frequencies and less non-linear distortion in the region of the main resonance of the woofer in comparison with other types of acoustic design.

Acoustic Systems with Bass Reflexes is a closed case with a dynamic woofer and an additional hole in which a piece of a round or rectangular pipe of a certain size is fixed for inverting and emitting a sound wave from the back of the dynamic head cone. The speakers with FI are often called simply a phase inverter, since the internal volume of the case and the pipe are involved in the inversion of the phase of the sound wave. The shape of the pipe section does not significantly affect the operation of the FI.

The resonant frequency of the FI depends on the internal volume of the housing, the cross-sectional area and the length of the pipe (the mass of air oscillating in the pipe), in the traditional version it should be close to the resonant frequency of the dynamic head in open space. The FI hole is an additional emitter of inverted sound waves from the back of the dynamic head diffuser in the FI resonance region, and the air oscillations in the tube are almost in phase with the oscillations of the direct radiation of the diffuser and are much larger in amplitude than the oscillations of the head cone due to the large acoustic resistance of the FI at the resonant frequency.

In other types of speakers, in the region of the main resonance of the dynamic head, the oscillation amplitude of the voice coil and diffuser increases significantly, and the asymmetry of the magnetic field relative to the coil begins to affectand non-linearity of the suspension of the moving system, distorting the shape of the sound signal .

In a phase inverter at these frequencies, the sound pressure is created mainly by the outlet of the pipe. Above the main resonance frequency, the radiation of the dynamic head increases, and the radiation of the FI hole decreases, but since they are almost in phase, their sound pressure is added. At higher frequencies, due to the increase in the reactance of the FI pipe, this speaker acts as a closed case .

The frequency response of the impedance modulus of a conventional dynamic driver in open space has one maximum at the fundamental resonance frequency. The phase inverter as an AU has two maxima located on both sides of the main resonance frequency of the head (curves 1 and 2 on rice. one), and the smaller the body volume, the greater the distance between the maxima and the dip between them. In order to obtain a smoother frequency response at low frequencies, some high-quality speakers install three tubes tuned to the frequency of the main resonance and the frequencies of the side maxima. If an LF head with a very low main resonance frequency is used in the speaker and the lower maximum is in the infra-low frequency region, then two pipes tuned to the frequency of the main resonance and the upper maximum will suffice. These solutions give positive results in terms of smoothing the frequency response, but complicate the design, and additional holes on the front panel worsen appearance AS. Speakers with slotted FI, which have become widely used by radio amateurs, as well as in industrial speakers and subwoofers, are less prone to organ resonances than speakers with round pipes.

Considering the absence of localization of radiation of lower sound frequencies, FI of all types can be placed on any walls of speaker cabinets or subwoofers. An example is a speaker with a slotted FI on the back wall, shown inrice. 2. If the FI is not placed on the front panel, then there must be gaps of at least 100 mm between its outlet and the walls of the room or furniture. In amateur and industrial speakers, in subwoofers, the wall of the case is often used to form a slotted FI. This solution is not only more technologically advanced, but also reduces its length by 15% compared to the calculated value, which is important for small speakers.

Considering the absence of localization of radiation of lower sound frequencies, FI of all types can be placed on any walls of speaker cabinets or subwoofers. An example is a speaker with a slotted FI on the back wall, shown inrice. 2. If the FI is not placed on the front panel, then there must be gaps of at least 100 mm between its outlet and the walls of the room or furniture. In amateur and industrial speakers, in subwoofers, the wall of the case is often used to form a slotted FI. This solution is not only more technologically advanced, but also reduces its length by 15% compared to the calculated value, which is important for small speakers.

Considering the foregoing, the author developed a design and then manufactured in  two copies of speakers with slotted FI. In the author's version, a slotted channel is used, the exit of which is almost invisible on the front panel ( rice. 3). In addition, to smooth the frequency response in the region of the main resonance of the LF head, the FI channel has a variable length ( rice. 4). The principle of operation of such a FI is described below.

two copies of speakers with slotted FI. In the author's version, a slotted channel is used, the exit of which is almost invisible on the front panel ( rice. 3). In addition, to smooth the frequency response in the region of the main resonance of the LF head, the FI channel has a variable length ( rice. 4). The principle of operation of such a FI is described below.

On the rice. one shown frequency characteristics dynamic head impedance modulus: curve 1 - in open space; 2 - in a phase inverter housing with a volume of 54 liters with a pipe; 3 - in the case of a phase inverter of a smaller volume; 4 - in a phase inverter housing with a volume of 54 l with a slotted channel of variable length.

The design of the AC loudspeaker with the main components is shown inrice. five.

The speaker used a low-frequency dynamic head 8GD-1 with a diffuser diameter of 200 mm (main resonance frequency 30 Hz, total quality factor Q,s = 0.33), which was used in the speaker "Victoria-001".

The optimal internal volume of the phase inverter housing for such a head is 54 liters. The external dimensions of the case of the author's version of the AC - 260x600x360 mm. The side walls are made of laminated chipboard 20 mm thick, and the front panel is made of plywood 12 mm thick, which is reinforced near the woofer with an overlay of the same plywood lined with veneer. The back wall of the case is made of plywood 12 mm thick. The side walls are fastened together with screws screwed into the side ends of the upper and lower walls with an interval of 20 mm. The heads of the screws protrude 10 mm and fit into corresponding holes drilled in the vertical walls to a depth of 12 mm and filled with epoxy.

The connection of the side walls must be carried out on a flat surface, laying them on it with their rear ends and inserting the back wall inside, the ends of which are wrapped around the perimeter with several layers of keeper or insulating tape (PVC), which ensures the correct shape, technological gap and prevents it from sticking to the walls. The top and bottom of the walls should be tightly fastened with bundles using twists for the duration of the resin polymerization. Immediately remove the resin that has come out with a swab moistened with acetone or a solvent for nitro paints.

After the polymerization of the resin, sheathe the front and rear parts of the case walls at a distance of 12 mm from the ends inside with slats with a section of 20x20 mm using short nails and PVA glue or epoxy resin, which will be needed to fasten the front panel and back wall. After performing all the necessary operations, the front panel is glued tightly, and the back is fixed with screws.

On the front panel, a block of high-frequency heads, a mid-range head with a shielding box, a low-frequency head and a PHI box should be fixed. Before gluing the front panel for ease of operation, the woofer must be removed. This assembly technology was used by the author as an experiment, but the option of attaching the walls with the help of rails is also quite possible.

To expand the radiation pattern in the band of the HF head 2GD-36 block  placed along an arc with a radius of 200 mm (rice. 6). To do this, they are installed on four extreme and four middle brackets made of sheet steel 2 mm thick (rice. 7, a, b), which are fixed to the aluminum frame with M3 countersunk screws. The framing of the HF unit consists of four walls of soft aluminum 5 mm thick, which are tightly fitted to each other and attached with screws to the inner rectangular wooden panel (rice. 8). Between the heads are glued partitions made of 1.5 mm thick electric cardboard, painted black. The HF unit is attached with screws to the front panel from the inside to the three rails fixed on it at the top, as well as along the sides of the hole.

placed along an arc with a radius of 200 mm (rice. 6). To do this, they are installed on four extreme and four middle brackets made of sheet steel 2 mm thick (rice. 7, a, b), which are fixed to the aluminum frame with M3 countersunk screws. The framing of the HF unit consists of four walls of soft aluminum 5 mm thick, which are tightly fitted to each other and attached with screws to the inner rectangular wooden panel (rice. 8). Between the heads are glued partitions made of 1.5 mm thick electric cardboard, painted black. The HF unit is attached with screws to the front panel from the inside to the three rails fixed on it at the top, as well as along the sides of the hole.

The principle of operation of a slotted FI with a variable length is to reduce the amplitude of oscillations of the woofer moving system not only at the frequency of the main resonance, but also at the frequencies of the side maxima. The average length of the slotted channel is equivalent to the length of the pipe tuned to the frequency of the main resonance of the dynamic head. Reducing the driver impedance modulus in a wider band will further reduce the amplitude of the voice coil and cone oscillation in this band, reducing the non-linear distortion of the speaker and, thereby, improving the sound quality of the speakers.

For a practical determination of the minimum and maximum lengths of the box, it is necessary  using a sound generator, determine the frequency of the main resonance of a real low-frequency dynamic head in open space visually by the maximum amplitude of the diffuser oscillations or more accurately - using an ammeter by the minimum current in the voice coil circuit. To determine the practical dimensions of a slotted FI, this head can be installed in the speaker cabinet, and the hole for the midrange or HF head (usually it is at least 70 mm in diameter) is proposed to be used to install a tuned pipe. It can be made from two cardboard or plastic tubes inserted into one another (chosen according to diameter) 70 ... 100 mm long. A larger diameter tube must be fixed through the O-ring in the hole for the midrange or treble head on the outside of the case. By supplying a signal from the sound generator with the frequency of the main resonance through the amplifier to the woofer and changing the length of the telescopic tube, it is necessary to achieve maximum acoustic vibrations at its output. This can be determined by the maximum deflection of the candle flame near the outlet of the pipe, or more precisely by using a microphone connected to an amplifier and a voltmeter. alternating current. As a result, the resulting length of the pipe will be equal to the length of the middle part of the box. These recommendations are given for the use of other types of low-frequency heads, if their fundamental resonance frequency is unknown or they have been modified according to methods that reduce this frequency.

using a sound generator, determine the frequency of the main resonance of a real low-frequency dynamic head in open space visually by the maximum amplitude of the diffuser oscillations or more accurately - using an ammeter by the minimum current in the voice coil circuit. To determine the practical dimensions of a slotted FI, this head can be installed in the speaker cabinet, and the hole for the midrange or HF head (usually it is at least 70 mm in diameter) is proposed to be used to install a tuned pipe. It can be made from two cardboard or plastic tubes inserted into one another (chosen according to diameter) 70 ... 100 mm long. A larger diameter tube must be fixed through the O-ring in the hole for the midrange or treble head on the outside of the case. By supplying a signal from the sound generator with the frequency of the main resonance through the amplifier to the woofer and changing the length of the telescopic tube, it is necessary to achieve maximum acoustic vibrations at its output. This can be determined by the maximum deflection of the candle flame near the outlet of the pipe, or more precisely by using a microphone connected to an amplifier and a voltmeter. alternating current. As a result, the resulting length of the pipe will be equal to the length of the middle part of the box. These recommendations are given for the use of other types of low-frequency heads, if their fundamental resonance frequency is unknown or they have been modified according to methods that reduce this frequency.

The walls of the slotted FI can be made of plywood with a thickness of 5 ... 6 mm according torice. 4and rails. A hole for the FI is cut out in the front panel under the block of HF heads, where it is fixed with glue.

In the author's version, the inner section of the box is 20x200 mm, which is equal to twice the section of a pipe with a diameter of 50 mm. Dimensions lmin = 55 mm, 1sr = 70 mm, Imax = 120 mm (see. rice. 4) are determined by experiments. It is rather difficult to achieve a flat frequency response in the region of the main resonance (the influence of room resonances should also be taken into account), but even a partial reduction in the side maxima in the speaker impedance improves the quality of reproduction of lower audio frequencies compared to conventional FI; Obviously, smoothing the load impedance is useful for a power amplifier.

In the mid-frequency link, a broadband head ZGDSh-8 (8 Ohm) was used, closed by a screen made of wooden slats and plywood 6 mm thick with internal dimensions of 105x105x35 mm. The cavity closed by the screen is filled with fluffy cotton wool and is attached to the front panel from the inside with four screws in the corners. During final assembly, all contacting surfaces of parts fixed with screws are covered with a thin layer of plasticine. There is no sound-absorbing material inside the main body of the speaker: in my opinion, the energy emitted by the back of the woofer cone should not be absorbed and converted into heat, but radiated through the FI. It effectively radiates vibrations only in the frequency band to which it is tuned, so the influence of reflected signals of other frequencies on the quality of playback was questioned. There were simply no complaints about the sound quality of this speaker. This does not mean that sound absorption for medium or high frequencies is contraindicated.

The speaker described here uses a three-band crossover filter with crossover frequencies of 500 and 5000 Hz, the circuit of which is shown inrice. nine. Coil L1 - frameless multilayer with an inner diameter of 35 mm, a winding length of 20 mm; it contains 120 turns of PEV-2 wire with a diameter of 0.6 mm. Winding is carried out on a wooden mandrel with a diameter of 35 mm with removable cheeks. Before winding between the cheeks, it is necessary to insert 3-4 strong threads, with which, after winding, you need to tie the turns of the coil, soak with varnish and dry. Coil L2 contains 200 turns of PEV-2 wire with a diameter of 1.2 mm, it is wound on the same mandrel.

In the crossover, you can use paper and metal-paper capacitors BGT, MBGP, MBGO, as well as K42-4 for a voltage of 160-250 V.

The filter parts are glued to the bottom of the speaker cabinet with quick-drying glue and connected with mounting wires to the dynamic heads and a connector on the rear wall for connecting the connecting cable between the speaker and amplifier. The wires leading to the connector should allow, if necessary, to freely remove the rear wall of the case.

In such an AU, dual woofers can be used, but the main task was to test the efficiency of the AU with a slotted FI of variable length.

In conclusion, it should be noted that despite the use of outdated dynamic heads, the sound quality of these speakers, connected to an amplifier with a low output impedance and a power of 10 ... 20 W (at a nominal load of 8 ohms), is assessed as very high.

LITERATURE

1.

Aldoshina I. A., Voishvillo A. G.High-quality acoustic systems and emitters. - M.: Radio and communication, 1985, p. 49.83, 124.

2.

Ephrussi M. M.Loudspeakers and their applications. - M.: Energy, 1976, p. 70-82, 106-109.

3.

Jean Piero Matarazzo.Theory and practice of the phase inverter. www.akycmuka.narod.ru

4. Museum of speakers. http://devicemusic.ucoz.ru/forum/22

5.

Zhurenkov A.Connecting parts from chipboard. - Radio, 1980, No. 1, p. 26.

6. Reference book of a radio amateur designer. Edited byN. I. Chistyakova. - M. Radio and communication, 1990, p. 195, 196.

And finally: the material was peeped on the site

A subwoofer is an element of a speaker system that reproduces the sound of audio tracks at the lowest frequencies. Having a good subwoofer is a music lover's dream, because everyone loves the high-quality sound of music in the car. However, such a device is not cheap. However, most car owners can calculate the box for the subwoofer and make it with their own hands in order to avoid unnecessary spending on the factory model.

How to choose speakers for your subwoofer

Subwoofers are used in cars to improve the sound of music at low frequencies. For normal listening to melodies or radio broadcasts, a standard audio system in a car is quite enough, but connoisseurs of loud and clear sound at low frequencies prefer to place a subwoofer in the cabin.

During the selection of speakers for a future product, the car owner learns that they can be round or oval in shape and size. Usually (based on the dimensions of the car interior), round speakers with a diameter of 10, 13 or 16 cm are selected, as well as oval ones with a length of 15x23 cm. Accordingly, the larger the speaker diameter, the better the sound will be reproduced at low frequencies.

How to know which car speakers are right for you

Front self-manufacturing subwoofer in a car, it is necessary to clarify several basic theses:

- the shape of the speakers does not affect the sound quality of music in the car;

- only the size of the speaker affects the depth and richness of the sound;

- it is necessary to think carefully about exactly what shape and size the speakers are needed so that the subwoofer looks appropriate in the cabin.

Design is not of paramount importance, therefore, when choosing a speaker, its technical characteristics are priority

Designing a homemade subwoofer

Car subwoofers are installed in the luggage compartment or on the rear shelf, so this system is called the rear.

The most serious moment in manufacturing is the determination of its size and device. Depending on the tasks set, the design can have a variety of variations.

Types of subwoofers

There are two main types of subwoofers. If we talk about the attitude to the sound power amplifier, then conditionally they are divided into:

- active. They have already built-in amplifier and crossover, which provide high quality sound and remove high frequencies from the sound. The active subwoofer receives signals from any source with which it has a connection;

- passive. The device is not equipped with additional amplifying elements, therefore it is connected to the main audio system of the passenger compartment. The only disadvantage of a passive subwoofer is that it seriously loads all the channels of the system, and therefore the sound quality also decreases.

Active subwoofers do not load the standard interior audio system, so they have better sound quality

Where to install: in the trunk or under the seat

If an active subwoofer can be placed almost anywhere, then the purity and power of its sound at low frequencies will directly depend on the location of the passive device. Depending on the preferences of the car owner and the availability of free spaces in different types of car, several places are offered for installation:

- in the center in front - the optimal position for communication with the front speakers, which will provide almost perfect sounding of tracks in the cabin. However, in most vehicles there is no space in the front to accommodate any large devices, so the central position in front is more suitable for minibuses;

- in the trunk, with the speaker directed forward - one of the most popular ways for drivers to place a subwoofer. Suitable for all kinds of vehicles;

- in the trunk, with the speaker directed backwards - more suitable for a hatchback car, since the sound wave does not encounter obstacles in its path. The location in the trunk back is unacceptable for sedan or coupe cars, as the sound will be strongly deformed due to the specific design of the luggage compartment;

- on the floor under the seat - another option, which, however, is not very popular with drivers. Due to the fact that the subwoofer is located flush with the floor, in addition, the cabinet is located under the seat, the sound encounters many obstacles in its path;

- on the back shelf - one of the best options placement of a subwoofer in all types of cars. The main condition is that the shelf must be wide and strong enough to withstand low-frequency bass.

Photo gallery: the main places to place the device in the car

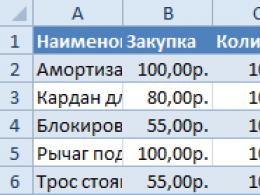

The program algorithm will take into account all the wishes and make the calculation of the volume and other parameters of the case quickly and correctly

What to make a box from

A subwoofer box is not just a box that contains a speaker. The box must comply with many of the dynamic laws of acoustics in order for the sound to be truly rich and clear. For the manufacture of different types boxes will require different materials, and manufacturing methods will in many ways be different from one another.

How to build a bass reflex subwoofer box

The standard version of a homemade subwoofer is a phase inverter. This is the simplest type of subwoofer, besides, its box is good because a special phase inverter tube allows you to reproduce low frequencies that are practically not perceived by the human ear. And the design of the box is quite simple, which makes its manufacture accessible to almost everyone.

Required tools:

- soundproofing;

- wood screws 50 mm long;

- drill;

- screwdriver;

- electric jigsaw;

- liquid Nails;

- sealant;

- PVA glue;

- carpet.

The case for placing a bass-reflex subwoofer must be as durable as possible and not transmit sound waves. For these purposes, multilayer plywood or high quality chipboard is perfect. The best option is to take a plywood sheet 30 mm thick.

For the manufacture of the case, you need to follow this plan:

- Prepare parts of the body: front, back, two side, bottom and top according to your calculations or the parameters displayed by the programs.

- Under the size of the speaker (for example, diameter 160 mm), cut a hole in the front of the case blank.

- Above the hole for the speaker, you will also need to cut a slot for the bass reflex tube and screw the bass reflex compartment to it.

- After two holes are made on the front panel, it is necessary to glue all the side parts of the box together, and then screw them together with self-tapping screws.

- In this case, it is especially important to tighten each self-tapping screw all the way, as the empty spaces between the panels will seriously distort the sound of the speaker.

- Next, on the back of the case, you will need to cut a small hole for the wires.

- Before connecting all parts of the case, we insert the speaker.

- Next, it is necessary to carry out the interior decoration of the case: for this, all joints and cracks must be smeared with resin or sealant to increase sealing, after which soundproofing fabric is glued to all side panels.

- After completing the interior decoration, you need to go to the outside: the body is covered with a Karapet fabric, and the fabric should also cover the slot for the phase inverter. Karapet can be stretched with a regular epoxy or a furniture stapler.

Once the speaker is fixed, wires are pulled from it through the hole and connected to acoustic system car.

Photo gallery: how to assemble a compact box with a phase inverter

The subwoofer can be connected independently, based on the parameters of this circuit

Before starting work, make sure that the vehicle battery is disconnected. This is a safety measure that will not only avoid damage to the speaker system, but can also save the health and performance of parts of the human body.

Video: connecting and setting up a subwoofer

Independent design, manufacture and connection of subwoofers in a car is available to almost every driver. The key to the success of the case will be both a competent calculation of the dimensions and volume of the product, and accurate assembly of the case. At the same time, the motorist can independently choose the desired size of the speakers in order to create the bass sound in the cabin that suits him best.