Modding the USB-to-SATA converter for your own needs. Modding the USB-to-SATA converter for your own needs Homemade usb sata ll adapter

The note sets out in an accessible form simple steps to adapt using improvised means of the USB-to-SATA converter to a form suitable for use.

Preamble

Once, for some (still unclear) reason, one of the on-board SATA nipples on a self-assembled NAS on miniITX (it is also an AoE server for diskless clients) failed, and since it was in the evening (and even on a long weekend ) then this imposed some restrictions on the availability of the solution (although you can fly into a convenience store with a bullet, but laziness, as you know, is the engine of savvy minds).So, the task is this: connect a SATA screw to a miniITX system in the absence of free SATA.

Part I

Having quickly carried out an audit of the near-computer trash, such an adapter was discovered, which had been gathering dust for many years, because it was ordered at the dawn of the popularity of foreign online stores:As it turned out, the board is not just a USB-to-SATA converter, but designed for devices such as laptop DVD drives that carry a mating connector on board slimSATA(differs in an additional non-standard power block). Thus, the adapter could not be connected to ordinary SATA devices and it was thrown into a dark corner of the box for a long time.

So, the adapter contains a slimSATA connector, which includes a standard SATA 7pin female connector (as on connecting cables):

Even if you bite out an additional non-standard slimSATA power connector from the board, then, being inserted into the HDD, the adapter will block access to the HDD power connector (SATA 15pin). There is only one way out - an extension cable for the SATA 7pin connector, for which we carefully cut off one of the ends of a standard SATA cable:

Now you can completely bite out the slimSATA connector from the adapter board and solder the end of the SATA cable (without interchanging the RX - TX diff pairs!):

To give mechanical strength to the junction of the cable and the board, it was decided to use PVC tape (I refused the initial idea to fill it with silicone sealant - it is not known how “non-conductor” it is at 1.5 GHz):

Now let's take a look at USB: since we need a replacement for the internal SATA, a two-meter skein from USB-A to USB-B inside the case will obviously be superfluous. We get rid of USB-B - we solder a piece of the board with connectors and electrolytes (they are needed only when powering a USB DVD drive).

We will connect the adapter to the internal USB comb on the motherboard. Why do we crimp / solder (for 480 Mbit / s - it’s better to solder) the contacts of the PLS-4 connector (of course, PLD-10 is more convenient, so that for the whole comb at once, but only PLS-4 was present in the household):

After checking the pinout of the comb on the motherboard and the USB pins of the converter chip SPIF225A, we assemble:

In total, after spending some time searching for the right pinouts, hastily an adapter of this kind was built, which made it possible to pick up a fallen off HDD without rebooting, and as a result, thanks to its dimensions and getting rid of atavisms, it fit quite harmoniously into the NASa interior:

Part II

After solving problems with the NAS and upgrading it, an itchy craving for perfectionism prompted the adapter to be modified. What were the required connectors ordered for: SATA 7pin male SMD& . We mark the seat for the SATA connector, we do it in such a way that the holes for the holding pins do not pass through the signal tracks on reverse side boards (as they say - try on seven times - cut one off drilled):We clean the copper and solder the holding pins on the back of the board:

The pin pitch of the footprint on the board and the SATA connector are the same, as a result we get a neatly soldered connector:

Let's take a look at the USB part. We mark and prepare a place on the board for landing miniUSB-B:

We solder the connector, showing virtuosity when working with a 0.65mm pitch of the miniUSB-B connector:

Here some explanations are needed, so, the sequence of actions with miniUSB-B:

- The GND contact, so as not to interfere neatly (the material of the legs is fragile - at the first connector it broke off the leg when bent), we bend it up and solder it to the case - then we solder the case to the GND of the board;

- The ID pin is not used - so we just pull it out of the connector with tweezers;

- Now it has become a little freer - there are three conclusions left - they must be carefully pushed apart with tweezers so that there is more space for maneuvering with a soldering iron;

- We solder small extension conductors to the D- and Vbus terminals, and slightly raise the inputs themselves so that they do not short on the board after installation;

- We leave the D+ pin "as is" - physically during installation, it falls on the corresponding polygon on the board;

- Now you can mount the connector on the board - we grab the case diagonally, then carefully deal with D- and Vbus.

The second version of the adapter turned out to be much more aesthetically pleasing:

Little touch

Everything is fine. Both functionality and aesthetics, but not enough zest. Looking through the documentation for the USB-to-SATA bridge SPIF225A, and she was found: " pin 36 - HDD Activity LED output". Fine:

We solder a 10K resistor (PullUp to suppress noise on the TriState-pin?) and solder a chain of series-connected R and LED. A resistor with a value of hundreds of Ohms (I took 1kOhm), an LED with a cathode to pin 36 of the microcircuit (determine by dialing or documentation):

Outcome

Using the example of adapting a USB-to-SATA converter, we showed a way to quickly refine it using a minimum of materials at hand (fast recovery of diskless clients), and also demonstrated an approach to a more thoughtful and elegant solution.

To access content from a PC or laptop hard drive via USB, you will need a special device - an adapter.

Connection is not difficult, the main thing is the presence of a special device. There are several types of devices that allow you to connect HDD(hard drive, HDD) of a desktop computer or laptop to USB and open its contents. Here are the two most popular: a universal USB controller (for example, AGESTAR FUBCP) or a case adapter (SATA External case, ITEC MySafe Advance and others).

In China, you can buy these built-in devices instead of a laptop drive:

There are also combined options with a complete set (adapter, cord, power supply).

The advantages of the first one are that such a device is cheaper than a case adapter, and often supports several types of connections (SATA, IDE). However, using a conventional hard drive as a portable drive is problematic with it, since it will not be protected by anything.

The second option is a case adapter, just designed to turn a hard drive into a portable memory device with a sufficiently large capacity, since the case will reliably protect against dust and mechanical damage. But at the same time, the versatility of the device suffers: before buying, you will have to decide which of the connectors the purchased adapter will support.

Using a hard drive in a case version is a fairly simple procedure, so let's look at how to connect and open a hard drive via usb using a universal adapter (for example, AGESTAR FUBCP).

Connection procedure

The first thing to do is to determine the type of HDD connector that you plan to connect via USB. Plugs are of the following types:

SATA (a more modern connector, used in freshly assembled PCs and laptops);

IDE (can be found mainly in "experienced" PCs).

We will consider the connection using the example of AGESTAR FUBCP, since it supports both "old" and modern HDDs. The average cost of such a device in Russian electronics stores is about 1,500 rubles.

The device is equipped with three interfaces (plugs):

- SATA (7-pin male).

- IDE 40pin (40-pin male, for IDE 3.5″).

- IDE 44pin (respectively, 44-pin plug, for IDE 1.8″/2.5″).

Description of AGESTAR FUBCP connectors below.

Step by step connecting HDD to computer

So, we have identified the connector of the connected hard drive, now it needs to be connected to the corresponding connector on the device. After that, insert the USB data connector (black) into the USB port of a computer or laptop. If we are working with a laptop hard drive (2.5”), we can turn on the adapter, and the HDD should appear in the list of computer drives. Sometimes with such a connection, the hard drive may not have enough power and will not be detected by the system. In this case, turn off and plug the red USB connector of the adapter into any of the ports on the computer and turn the adapter back on.

If the connected hard drive was previously installed in a PC (3.5 ”), it will not have enough power from your PC's USB. Complete with AGESTAR FUBCP there is a power supply for hard drives 3.5" format. To open the hard drive via USB, first we connect it to the appropriate connector (IDE / SATA), after that we insert the black USB cable into one of the computer's USB ports, then we connect the power supply that works from 220 V to the adapter (plug it into a socket) .

After all the cables are securely connected, turn on the adapter. The connection is completed, hdd will be detected by the computer, and it will be possible to work with it.

Introduction.

Most laptop owners sooner or later face the problem of lack of space on. As a rule, laptops up to and including 15 inches do not have a free second slot for a 2.5 inch device. Therefore, owners are forced to think about either replacing the laptop itself, or replacing its hard drive. After replacing the hard drive, it always remains old drive, which can be easily converted into external USB data storage drive.

Naturally, you can purchase a mobile 2.5 inch hard drive and turn it into external drive. Fortunately, the cost of external drives allows this. For example, at the time of writing, a 250 GB mobile hard drive costs $40, while a 500 GB device from WD costs only $45.

Decide on the type of hard drive.

In fairness, it should be noted that an ordinary desktop 3.5-inch hard drive can also be turned into an external drive - you just can’t call it mobile anymore. If you have an unused 2.5 or 3.5 inch hard drive, then first of all you need to determine the type of its interface.

To date, the following interface types exist on the market: IDE (ATA) and various SATA options. As a rule, all SATA interfaces are backward compatible with each other, and we will not dwell on their variations. The situation is completely different between IDE and SATA interfaces, which are absolutely incompatible with each other and have different connectors.

Image is clickable --

The figure shows two hard drives with different interfaces. Winchesters have a mobile format of 2.5 inches. On the left is a hard drive with a SATA interface, on the right is a hard drive with an IDE interface.

Image is clickable --

In our hands was a 250 GB hard drive from western digital Scorpio Blue series with SATA interface. This drive been used for a long time in Acer laptop, but its capacity was not enough, and it was replaced by a more capacious 500 GB solution.

Image is clickable --

Despite long-term use, the hard drive did not cause any complaints, so it was decided to use it as an external mobile drive. To do this, it was necessary to find an external case for him, which we did. External case AGESTAR for 2.5 inch mobile hard drive.

Computer hardware stores offer a wide variety of external cases for 2.5 inch hard drives. Their key difference is this:

- body material,

- type of external port (interface),

- cost.

As a rule, various cases are presented in stores with USB interface 2.0, there are much fewer cases with eSATA interface, even fewer cases with their combination of USB 2.0 & eSATA. Several cases with a modern USB 3.0 interface were found on sale, but their cost exceeded the cost of the hard drive itself, so we did not consider them.

The key difference between USB 2.0 and eSATA is the transfer speed. Using the USB 2.0 interface allows for maximum compatibility, as these ports are available on all computers. A significant disadvantage of the USB 2.0 interface is - low speed data transfer, which will not allow you to unlock the full speed potential of your hard drive.

The eSATA port is more promising, but it is not common and is found only in expensive versions of motherboards, cases and laptops. The eSATA interface allows you to fully unlock the potential of SATA devices.

The material of manufacture can also be very different. Simply put, it's plastic. In more expensive variations, an aluminum case with a leather case is included.

The cost of external cases also varies. The cheapest option will cost the user 3 dollars, expensive versions will cost more than 100 dollars.

Purchasing a $100 case for a hard drive that costs less than $40 when new and is half the price once it's in use is wasteful to say the least. Therefore, for testing, we were given a case worth a symbolic 3 dollars - AgeStar SUB2P1. Completion and external inspection AgeStar SUB2P1.

Image is clickable --

From a device worth three dollars, we did not expect any miracles, both in terms of equipment and in terms of performance. The device comes modestly packaged in a package. The front wall of the device is covered by a cardboard box listing the key characteristics of the device. It is support for 2.5 inch mobile hard drives or solid state drives with SATA interface, the presence of a transmission interface USB data 2.0 and various options colors.

In fairness, it should be noted that our suppliers have confirmed that they have not seen any other than the black color of this case.

Image is clickable --

After opening the package, we were pleasantly surprised by the fact that the set includes an instruction manual completely in Russian.

Image is clickable --

The case is completely made of plastic. There are paper stickers on the front wall indicating the model, which will be erased in any case, so we recommend that you immediately remove them from the surface of the device.

Image is clickable --

The material of the case is soft black plastic, which does not smell anything, is uniform throughout its structure.

Image is clickable --

The covers of the device come off in two different directions, which makes it easy to remove and install the hard drive in an external case.

Image is clickable --

The two sides of the outer case are fixed with a plastic latch made from the material of the case. Thanks to the recesses on the walls, the lids are securely fixed and spilling a glass of liquid, or leaving the device in the rain, is unlikely to lead to any problems.

Image is clickable --

The device is designed for SATA hard drives, which we have repeatedly emphasized. Inside soldered controllers with SATA ports for power and data transfer.

Image is clickable --

Mini is soldered on the side wall USB port to transfer data and power the hard drive. There is no additional port to provide power to the drive, which may cause some problems for users. With a weak power supply that lowers the voltage along the 5 volt line, you often have to deal with problems starting the hard drive. Typically, connecting a drive directly to a port on motherboard and not on the body system block, the use of quality USB cable allows you to forget about this problem.

Image is clickable --

Sellers of computer components often talk about the presence of a USB data cable in the kit as an advantage of one or another external case or offer to purchase it separately if it is not. We advise our users not to pay attention to this, as a mini-USB-to-USB cable is usually found in almost every family and is often supplied with mobile phones. In our case, we successfully applied a stale data cable from mobile phone Nokia.

Image is clickable --

The next step is to install the hard drive in the case. This is done quite simply - by light pressing. Most importantly, first rotate the hard drive correctly according to the SATA power and data ports located in the case.

Image is clickable --

The absence of any protruding elements on the hard drive controller circuit allows you not to worry about its rear surface when transporting and using the device.

Image is clickable --

Some users may argue that the plastic case does not provide adequate heat dissipation from the hard drive. Naturally, external cases made of aluminum cope with this task much more efficiently. At the same time, we should not forget that mobile hard drives do not have such a high power consumption to suffer from overheating, and in laptops, as a rule, they are not cooled by anything else.

Image is clickable --

After the assembly of the device is completed, the stage of its testing and use begins. The power supply to the device is accompanied by the glow of the blue LED, which also symbolizes the user about the data transfer process. It should be noted that not everyone will have a smooth start with the created external drive. If the hard drive has already been used, it has been formatted and partitions have been created on it, you will not have problems getting started. It will be defined as a regular USB flash drive using the Plug & Play method. But for those users who have purchased a new hard drive without formatting and with no partitions, there will be a problem that will be associated with the absence of a drive letter in the "My Computer" tab.

To do this, you need to create partitions on the hard drive and format it. This can be done through various boot disks, but it's better not to bother and do it in the Windows operating system itself.

Image is clickable --

To do this, you need to go to the "Control Panel" through the "Start" section, then visit the "Administrative Tools" section. IN this section select "Computer Management", where in the "Disk Management" tab you can partition and format the newly connected external drive. After creating partitions, formatting them, you will have access to them through the "My Computer" tab and you will be able to exchange with the drive, as with a regular hard drive. Test configuration.

The assembled external drive was tested both on a desktop computer, based on a modern processor core i7 and a no less modern motherboard, as well as on an Acer Aspire 7730 laptop based on a Core 2 Duo processor. It should be noted that the level of performance on two different systems turned out to be comparable equal.

1. Data reading speed was tested in HD Tach 3.0.4.0

Image is clickable --

It's nice to note that the external drive we've assembled shows much more high level performance than the previously tested external hard drive WD My Passport Essential. Max Speed data transfer was 34.3 Mb / s, and the average delay was about 17.9 ms.

2. Data reading speed in HD Tune 4.5.

Image is clickable --

In the second synthetic test, we got similar data to the previous ones, which also turned out to be slightly better than that of the official WD My Passport Essential external hard drive.

3. The speed of writing files of 64 MB in HD Tune 4.5.

Image is clickable --

Somewhat more valuable is testing close to practice, by writing 64 MB files. IN this test we got quite expected results, which were also limited only by the capabilities of the USB 2.0 interface.

Separately, I would like to note that during the entire testing, the temperature of the hard drive did not exceed 35 degrees Celsius, while a similar hard drive installed in a laptop had a temperature of about 43 degrees. Therefore, users will not need to worry about the working conditions of the hard drive in this case.

4. Download speed operating system Windows 7.

In the course of practical testing on the speed of loading the image of the operating Windows systems 7, we got similar results for other USB 2.0 external drives.

5. Evaluation of drive performance in Windows environment 7.

We tested the performance of the external drive we assembled using the Windows 7 operating system. To do this, in command line you need to call the command: "winsat disk -drive g -ran -write -count 10", where "g" is the letter of the drive under test in the system.

From the test results, it can be seen that the drive we assembled received a much higher rating than the factory WD My Passport Essential solution.  Conclusion.

Conclusion.

According to the materials of this article, it is clear that any mobile hard drive can be turned into a good external drive without any hassle. Especially for testing, we asked to provide us with the cheapest external case, worth $ 3. Three dollars allows you to get an excellent external drive from a mobile hard drive, at least for data storage. Not to mention the fact that the same external case facilitates the recovery of data from the hard drive of "dead" laptops.

Despite the fact that AgeStar products are criticized by many for their low quality, after many years of using it, I have only a positive impression of it. First of all, it is for a democratic cost. Marriage occurs in all manufacturers, even if AgeStar has a slightly higher figure than Thermaltake. But the latter has no analogue to the presented external case for three dollars and with a guarantee of 6 months. We award AgeStar products with a gold medal for the best performance/price ratio.

In the era of computer technology, the speed of development of ports for the communication of the latter also does not graze the rear. Another thing is that end users do not need such a race. They did not have time to buy one device, but it no longer fits. Today we will deal with sata-usb adapters.

- What will be required

- Instruction

- Adviсe

- Worth paying attention

What will be required

- Chip converter;

- Printed circuit board;

- Soldering Station;

- Programmer.

Instruction

In order not to torment busy visitors, let's say right away that it is prohibitively easier and cheaper to go to the nearest computer store, pay the equivalent of a couple of US dollars and get a known working device, spending up to an hour of your time on it.

Further article for people who do not tolerate slippery beliefs, requiring evidence, or simply inquisitive individuals.

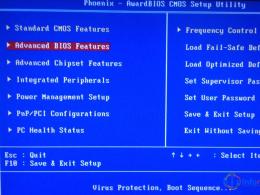

1. You should start by getting a converter chip. Since the usb / sata protocols are fundamentally different, there is no way to "solder that conductor here, and this one here, and everything will work." In this case, signal conversion is required, which can only be done by a chip made specifically for the task of converting usb to sata. The figure shows one of the varieties of such chips.

2. Now you need printed circuit board. This is the "plate" on which the elements are attached. Considering that the board must be completely custom-wired for your device, it is impossible to buy one. How to make the board itself is a topic worthy of another 10 articles and equipment for a tidy sum (if there is such a thing - super, you're in luck).

3. You will need a soldering station to solder the chip onto the board and organize the wiring.

4. Finally, if you are a magician and you have completed all the previous instructions, your magic will be required further. After receiving the finished board, you will need a programmer - a device designed specifically for your board in order to program it exactly for specific needs.

If you have completed all the steps and are bored, can you try to make a sata ide adapter on your own and from vga to a tulip? We read, learn, try - unsubscribe about the results.

The cost of manufacturing a device with your own hands, not taking into account all the equipment, will exceed the store price tag by 30-200 times. Is it worth it?

Clearly.

Worth paying attention

You will have to perform each step of this instruction 15 times, since the work is microscopic, and a speck of dust that accidentally gets in will nullify all the work done. Perhaps, if you have nothing to occupy your inquisitive mind, you should make something simpler, for example, a homemade robot?

How to make DIY sata usb adapter2.90 out of 50 based on 29 voters. Thank you for the article - like it. A simple click, and the author is very pleased.

How to make a sata ide adapter. Do it yourself

Storing information on your personal computer takes care of the hard drive. Progress, as you know, cannot stand still, so its speed and reliability are constantly improving. Generational change also entails a change in interfaces. Today we will talk about sata ide adapters.

- What will be required

- Instruction

- Adviсe

- Worth paying attention

What will be required

Instruction

Let's not hide the fact that Sata-type connectors are the development of ide-connections, the latest standard, nevertheless, is correctly called ATA. After the Sata interface appeared on the market, ATA was renamed PATA. As you may know, the bus running ide boasts an operating frequency of 33MHz. If we return to sata interface, the operation of its bus is determined by a frequency of 1.5 GHz. The difference, you see, is decent.

This immediately dismisses the possibility of the concept of "adapter", because it is impossible to passively connect two devices operating on different frequencies- For this, a special device called a converter is used. Its task is to remake the incoming signal of one protocol into another, understandable for the second device.

1. We will show clearly in the figure what a standard adapter-converter for ide and sata consists of.

2. As you can see, the front part is responsible for connecting the ide-cable, the back is provided for sata. The microcircuit in the center of the board is the same controller responsible for converting the incoming signal into the desired output. You can also notice the power connector - it is needed for the crystal oscillator (shiny "bath") and the controller.

3. Work on "homemade" does not stand up to criticism after finding out the cost of the device in the store. The proof below should absolutely discourage you from wasting a lot of your time on a fairly easily accessible and cheap device.

The price of $4-15 is a great indicator.

Also find out if you can make an adapter from vga to tulip and sata usb with your own hands.

Remember that any production of electronics at home cannot boast of proper security. You will have no one to complain to if your hard drive and controllers on the motherboard burn out due to the connection of a foreign device.

If you think you smell something fried, check your CPU temperature.

Worth paying attention

You can visually consider another representative here.

How to make a sata ide adapter. DIY3.00 out of 50 based on 10 voters. Thank you for the article - like it. A simple click, and the author is very pleased.

DIY sata cable

Hello friends, readers and visitors of my blog. In this article I will talk about sata cable. It is known that all manufacturers computer technology switched to sata power long ago.

This article will describe all the nuances of creating a sata cable or else it is called sata adapter, with your own hands. And so we begin the process.

Sata cable or sata adapter

For starters, we need a non-working PC power supply. And from the power supply you need to pull out the longest sata cable.

The longest cable is desirable, but if this is not available, of course, a short one can also be used.

In most cases, it happens that some other connector is attached to the sata cable. You can leave it on and take it off if you don't need it or if it gets in the way for some reason.

In my case, two wires on the additional connector were cut off and in order to get rid of the unnecessary molex connector, I had to disassemble the sata adapter.

Disassembling a Sata cable

This connector is very easy to disassemble. All wires on the sate sit on plastic latches that need to be lifted with the tip of a pair of scissors.

Without releasing, we pull the wire back, without effort and without damage, the wire is carefully removed from the connector.

To cut off the extra wires from the molex, I use a tool in the form of wire cutters from a women's manicure set. You can also use small electrical wiring pliers.

Once all the extra wires are cut off, insert the wires into their places. Attention when removing the wires, do not remove them all at once, otherwise you will get confused.

Remove one wire, cut off the excess and insert it back. And we clean the cut ends of the wires for soldering.

Molex parsing

We will connect the cable made on sata to our computer power supply via a molex connector

To do this, you will have to disassemble the molex connector itself. We take a free molex connector on the power supply and disassemble it. Tips on wires in molex have lugs or lug,

which keep them in the connector itself. To remove the four wires, we need to find these ears and bend them inside the tip. Use a bright flashlight to find this ear.

If the lug is not located, we pass a thin screwdriver or scissors around the tip

Once all the wires are removed, you need to solder the cleaned ends of the wires of the sata cable. Solder each wire by color. If for some reason it was not possible to understand, you can do the following. We take the wires of the sata cable, clean their ends by about 1.5 cm and wind them onto the tip of the molex and twist them so that they do not slip.

As we said above, the lugs of the molex wires are held on the ears in the connector and therefore, before putting the wires in place, you need to bend the tab on each wire

We assemble the molex connector and connect the sata power. It remains only to check the sata adapter. In my case, everything works to this day.

How to quickly make a sata cable

There is another option to make a sata adapter. To do this, as usual, take a sata cable, clean the ends by about 1.5 cm, twist the ends of the wires so that

Attention this method is not safe because at any time the wire can jump out of the plug and short out.

Do not use conventional adhesives otherwise it will be very difficult to disassemble the connector.

Why was the article written?

I once encountered cases that my power supply did not have enough sata cable for power due to hard drives.

It would be an option to throw a cable from one hard drive or go to the store and buy a sata adapter.

But since I like to create something with my own hands, I decided to make this cable myself. And step by step went through the process.

life-pc.com

You need to connect an external HDD 2.5 to 500 GB to the laptop. / hdd:

sata esata hdd sandboxNeed to connect external HDD 2.5 for 500 GB to the laptop. It is undesirable to fork out for the purchase of an adapter, and do-it-yourself work always gives + to the mood when using)

Here is the hard drive itself with a SATA connector

The 5V USB power connector seems to work, but is it possible?

And the most difficult thing is how to connect the part through which information is transmitted to the laptop? Has a SATA adapter

I thought about cutting and soldering the eSATA input and connecting it to the laptop, but again the question arises, is it possible to do this? Rummaged through the net who writes what is possible, someone writes what is impossible. If there is such an opportunity, which wires go where? and are there other ways? maybe someone will throw off a simple scheme?

Expand

joyreactor.cc

Make a do-it-yourself sata usb adapter photo

You can make an external hard drive yourself using ordinary SATA 2.5 or SATA 3.5 drives + a special cable or an external HDD case.

Let me explain for those who don't know:

SATA 3.5 are common hard drives that are used on your computer.

SATA 2.5 is a smaller version of the hard drive used in laptops.

If you purchase a simple USB-SATA adapter cable from the store, any hard drive can be used as an external hard drive by connecting it to any computer.

The method described above can be used, for example, to recover data, check disks for health, or use it as removable hard disk. The last option is not very convenient. So how are u external device there should also be a beautiful body.

I'm going to the store. We buy a case for external hard drive and stick SATA 2.5 into it.

For example, I bought a case for 300 rubles that allows you to work at USB 3.0 speeds and inserted a hard drive from an old laptop with a capacity of 160 GB into it.

What happened in the end can be clearly seen in the pictures.

Alexander Borisov, Samara

Specially for the site.

09.07.2015

Hello friends, readers and visitors of my blog. In this article I will talk about sata cable. As you know, all manufacturers of computer technology have long switched to sata power supply.

This article will describe all the nuances of creating sata cable or else it is called sata adapter, with your own hands. And so we begin the process.

For starters, we need a non-working one. And from the power supply you need to pull out the longest sata cable.

The longest cable is desirable, but if this is not available, of course, a short one can also be used.

In most cases, it happens that sata some other connector is attached to the cable. You can leave it on and take it off if you don't need it or if it gets in the way for some reason.

In my case, two wires on the additional connector were cut off and in order to get rid of the unnecessary molex connector, I had to disassemble the sata adapter.

Disassembling a Sata cable

This connector is very easy to disassemble. All wires on the sate sit on plastic latches that need to be lifted with the tip of a pair of scissors.

Without releasing, we pull the wire back, without effort and without damage, the wire is carefully removed from the connector.

To cut off the extra wires from the molex, I use a tool in the form of wire cutters from a women's manicure set. You can also use small electrical wiring pliers.

Once all the extra wires are cut off, insert the wires into their places. Attention when removing the wires, do not remove them all at once, otherwise you will get confused.

Remove one wire, cut off the excess and insert it back. And we clean the cut ends of the wires for soldering.

Molex parsing

We will connect the cable made on sata to our computer power supply via a molex connector

To do this, you will have to disassemble the molex connector itself. We take a free molex connector on the power supply and disassemble it. Tips on wires in molex have lugs or eyelets that hold them in the connector itself. To remove the four wires, we need to find these ears and bend them inside the tip. Use a bright flashlight to find this ear.

If the lug is not located, we pass a thin screwdriver or scissors around the tip

Once all the wires are removed, you need to solder the cleaned ends of the wires of the sata cable. Solder each wire by color. If for some reason it was not possible to understand, you can do the following. We take the wires of the sata cable, clean their ends by about 1.5 cm and wind them onto the tip of the molex and twist them so that they do not slip.

As we said above, the lugs of the molex wires are held on the ears in the connector and therefore, before putting the wires in place, you need to bend the tab on each wire

We assemble the Molex connector and connect sata nutrition. It remains only to check sata adapter. In my case, everything works to this day.

How to quickly make a sata cable

There is another option to make a sata adapter. To do this, as usual, take a sata cable, clean the ends by about 1.5 cm, twist the ends of the wires so that

Attention, this method is not safe, since at any time the wire can jump out of the plug and close.

Do not use conventional adhesives, otherwise it will be very difficult to disassemble the connector.

Why was the article written?

I once encountered cases that there was not enough power on my power supply sata cable for power from hard drives.

It would be an option to throw a cable from one hard drive or go to the store and buy a sata adapter.

But since I like to create something with my own hands, I decided to make this cable myself. And step by step went through the process.

You will be interested